Downtime

Reducing your Downtime is key to improving your manufacturing productivity. Learn about Downtime and how to reduce it from the articles linked below.

Learn About Downtime

Downtime Reduction Strategies

Downtime is the largest source of lost production time for most manufacturers. This page outlines practical tips for how to reduce Downtime that don't require a lot of external resources.

9 minute read

Operational

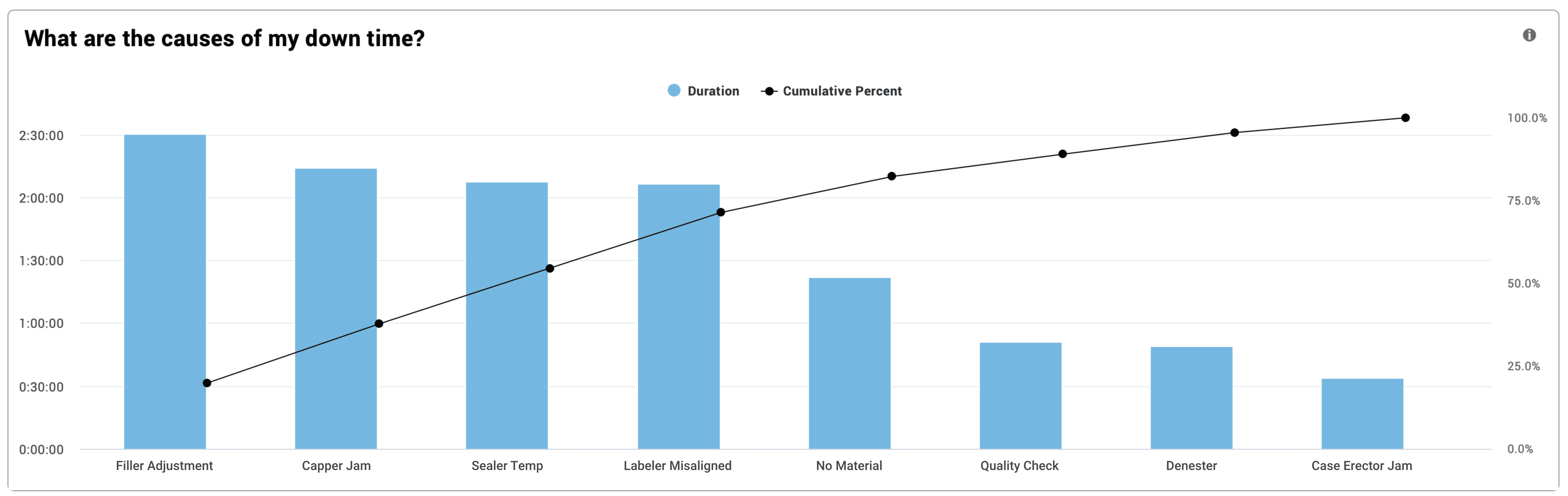

Optimizing Downtime Reasons

When assigning reasons to Downtime events, Downtime reporting is more consistent and more useful with a smaller list of down reasons. We recommend that manufacturers optimize their Downtime reason codes to the smallest set of reasons that are truly actionable.

5 minute read

Tactical

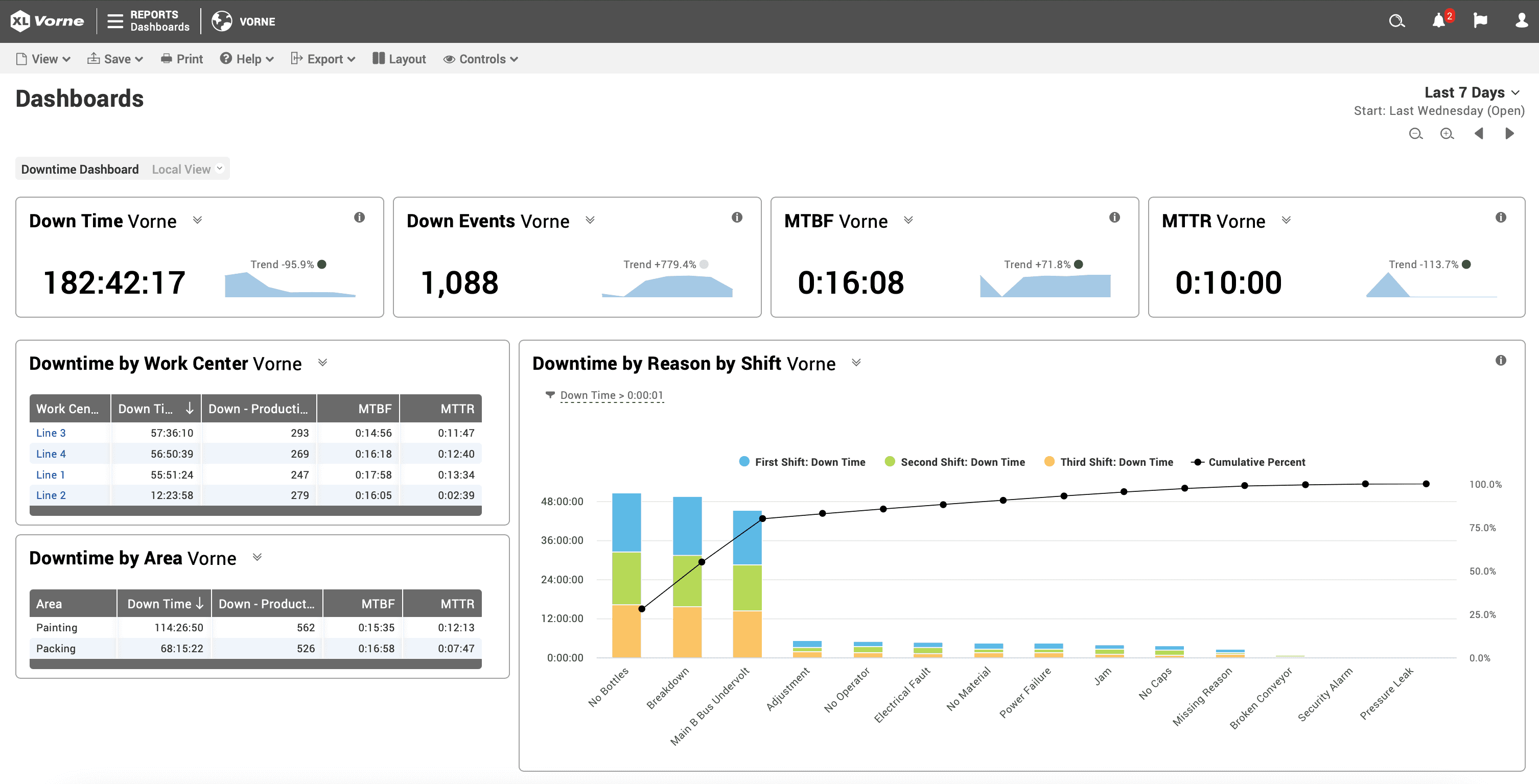

Reduce Downtime

Begin reducing downtime by establishing consistent measurement standards and ensuring downtime is captured at the process constraint. Then you can apply quick win strategies, such as providing real-time downtime data to operators, asking them to assign reasons to each down event, and attacking the largest sources of downtime.

6 minute read

Strategic

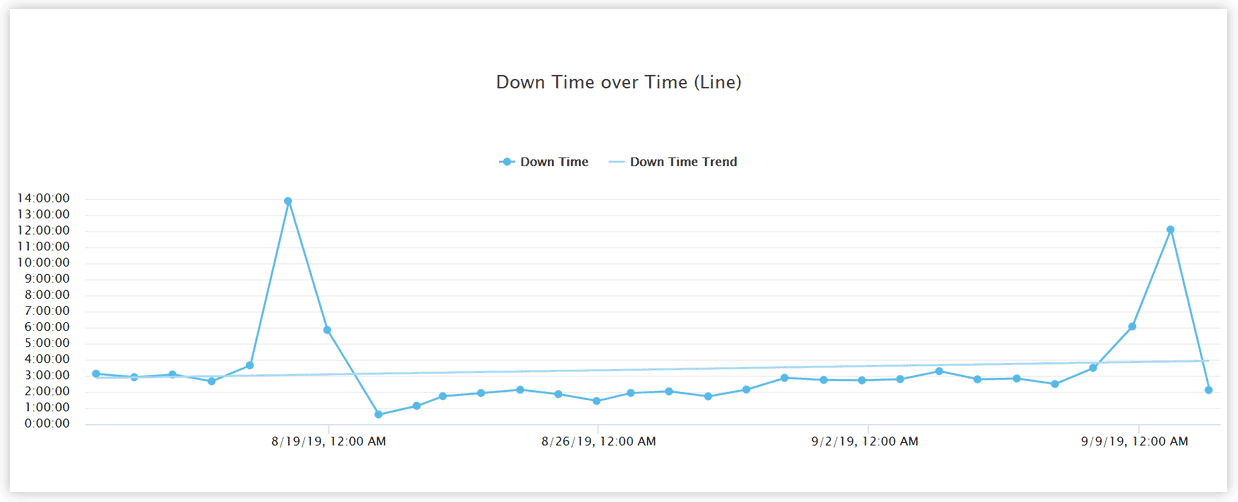

Machine Downtime Tracking and Reporting

Downtime tracking is an important aspect of improving manufacturing productivity. Downtime is the largest source of lost manufacturing time for most companies while also being one of the easiest losses to track and act upon. However, machine downtime tracking is only helpful if you go beyond collecting metrics - to presenting, analyzing, and improving.

12 minute read

Strategic