Short Interval Control (SIC)

What Is Short Interval Control?

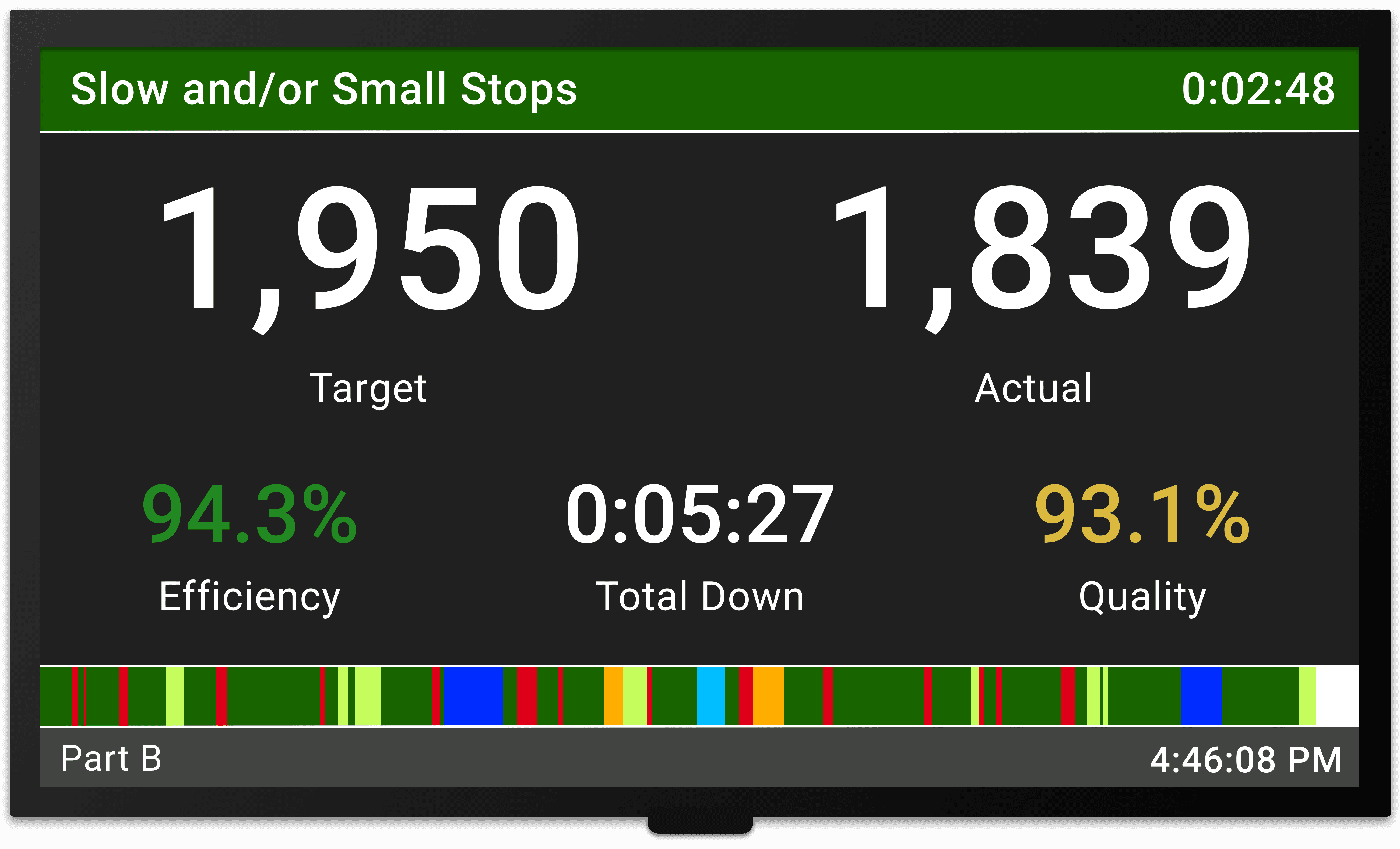

Short Interval Control (SIC) is a factory-floor process for driving production improvements during the shift. Each shift is split into short intervals of time (four hours initially), within which plant-floor employees use data to identify and implement improvement actions. These improvement actions may be countermeasures to ongoing or emerging problems, or they may be actions to improve existing production.

SIC can be seen as a form of Kaizen, as it encourages teams to work together to achieve regular, incremental improvements to the manufacturing process.

Why Use Short Interval Control?

Short Interval Control is a logical extension of the Daily Production Meeting. The underlying principle is the same: we cannot change the past; however, we can learn from it to improve the future. SIC accelerates the pace of improvement and puts more responsibility into the hands of operators and other plant-floor employees. SIC is very engaging for operational teams, as it provides them with a greater degree of autonomy and responsibility for how equipment runs, and it provides instant feedback through visible and measurable results.

SIC Meetings

What are SIC Meetings?

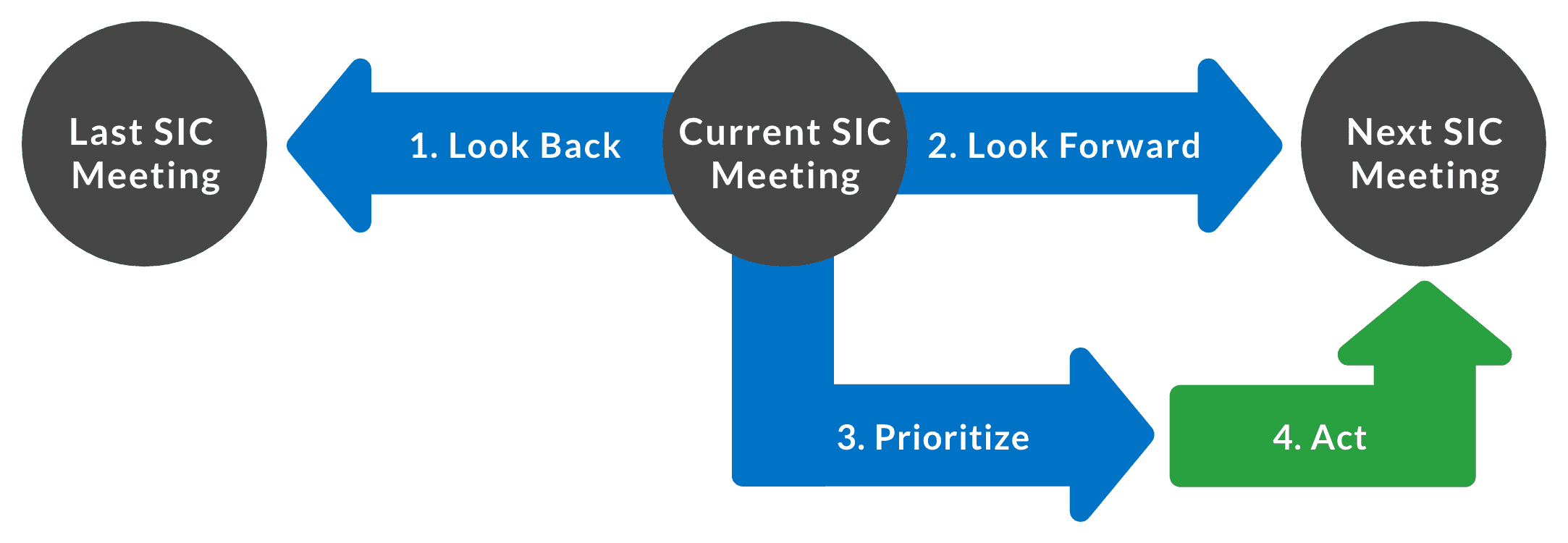

SIC meetings are structured, factual, proactive, and time-boxed. They are intense bursts of focused energy with one simple objective: identify one or more actions that will make the biggest difference to production during the next interval. SIC meetings are held on the plant floor and are typically completed in less than 10 minutes. They consist of three parts:

- Look Back

- Look Forward

- Prioritize

Look Back

In the first part of the SIC meeting, look back at the immediate past (the previous interval) for insights that can be applied to the immediate future. In practical terms, identify Top Losses from the previous interval and brainstorm countermeasures.

Look Forward

In the second part of the SIC meeting, look ahead to the immediate future (the next interval) to identify events that may adversely affect production. In practical terms, look for changing conditions such as changeovers, shift handovers, or material changes, and brainstorm preventative countermeasures (typically ways to prepare in advance).

Prioritize

In the third part of the SIC meeting, prioritize ideas and select a small set of specific actions to implement during the next interval. Think of actions as something that will fix, stabilize, prepare, or improve.

SIC Actions

SIC Actions are implemented by the plant-floor team during the SIC interval, with the goal of maximizing production. Actions that cannot be completed within the interval or that require additional resources are escalated for review outside of the SIC process (to a supervisory or managerial level).

Experience has shown that an effective implementation of SIC can improve OEE by as much as 10% (e.g., from 60% to 66%) in three to six months.

Benefits of Short Interval Control

In the short term, Short Interval Control is an effective tool for improving OEE with minimal capital investment. It does require an investment in training.

In the long term, Short Interval Control helps to create a culture of continuous improvement, where operators are actively engaged in suggesting and implementing improvements on an ongoing basis.

Team Member Roles

Short Interval Control involves the following roles:

| Role | Description |

|---|---|

| Manager | Create process. Standardize form. Lead meetings until process is established. Provide hands-on training. Periodically audit process. |

| Supervisor | Lead meetings after handover. Engage and motivate operators. |

| Operator | Identify and implement improvement actions. |

Key Insights for SIC

Expand the Process

It's best to start SIC as a very simple process (e.g., four hour intervals with one action for each interval). Once the base process is established and effective, consider expanding the process. There are three dimensions of expansion to consider:

| Dimension | Description |

|---|---|

| More Often | Add in another meeting. A fully developed SIC process has meetings every two hours (with the benefit of more frequent course corrections). |

| More Actions | Add in another action. A fully developed SIC process has two or three actions per interval (with the benefit of more opportunities for improvement). |

| More Accountability | Add in a review mechanism. A fully developed SIC process establishes improvement targets (Look Forward) and reviews those targets (Look Back). |

Focus on Four Types of Actions

SIC is primarily a factory-floor process, with actions completed by operators within the current SIC interval. As such, it helps to train operators to focus on specific types of actions that are well-suited to delivering improvement within a short interval.

| Action | Objective | Question |

|---|---|---|

| Fix | Carry out an immediate fix for an existing problem. | What can we do right now to fix this problem? |

| Stabilize | Apply a temporary measure to control an existing problem. | If we can't fix it, what can we do right now to stabilize it? |

| Prepare | Plan ahead for an upcoming event such as a changeover. | How can we best reduce the impact of...? |

| Improve | Proactively improve throughput, equipment, processes, or documentation. | Any ideas for quick improvements to...? |

Escalate Problems and Solutions

The Need for Escalation

SIC focuses on immediate action. As a result, there will be some problems and solutions that are best handled outside of SIC. The preferred way to do this is to couple SIC with a process that escalates unhandled problems and solutions to a higher level of management review.

Unhandled Problems

Some problems will be too intermittent or too big to effectively handle within SIC. Or, a problem may be stabilized in SIC but still need a longer term fix. It is important to capture these problems and escalate them outside of the SIC process.

Unhandled Solutions

Ideas that are beyond the scope of SIC may come up during SIC meetings (e.g., ideas that require capital expenditures or significant equipment redesigns). It is important to capture promising ideas and escalate them outside of the SIC process.

Standardize Your SIC Process

The most effective SIC processes are highly standardized (i.e., they are captured as Standardized Work) and thus very efficient. This is especially important when SIC is expanded to more intervals and more actions. Use a simple form to standardize the process, and display it in the work area to communicate planned actions.

Short Interval Control Template

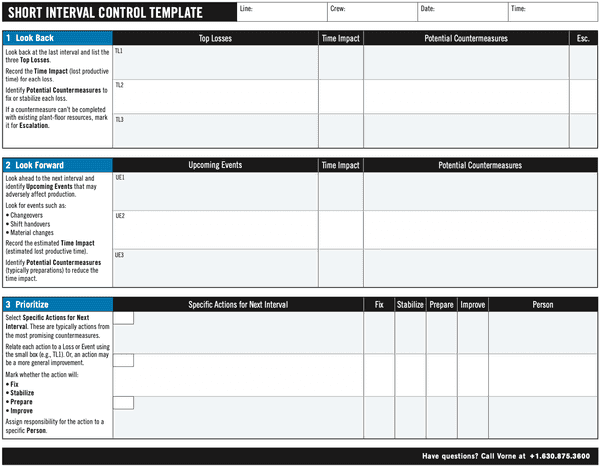

Below is an example of an SIC template. It is designed around the steps of Look Back, Look Forward, and Prioritize, with space to also assign Actions. Your team can use it as a starting point for your implementation of SIC.

Level and Difficulty

The Level is Foundation. SIC is a highly effective way to engage plant-floor employees in the improvement process.

The Difficulty is Medium. The basic SIC process is straightforward; however, it requires discipline and experience, and is most effective when the team is trained in problem-solving skills.

Rate Yourself on SIC

How good is your site at Short Interval Control? Answer ten simple questions to see how close you are to a model implementation.

| Question | ✔ |

|---|---|

| 1. Are there at least two SIC intervals within each shift? | |

| 2. Are SIC meetings completed in less than 10 minutes? | |

| 3. Are Top Losses identified (with countermeasures)? | |

| 4. Are upcoming events identified (with countermeasures)? | |

| 5. Is at least one action selected for each interval? | |

| 6. Are most actions completed within one interval? | |

| 7. Are a mix of actions completed (fix, stabilize, prepare, improve)? | |

| 8. Are problems escalated if they cannot be addressed within SIC? | |

| 9. Are ideas escalated if they cannot be implemented within SIC? | |

| 10. Are SIC meetings run with a standardized agenda and form? |

Comments or Questions?

We welcome your comments and questions. Contact us at: info@vorne.com.