Top Losses and Production Loss Analysis

What Is Top Losses and Production Loss Analysis?

One of the fastest ways to improve manufacturing productivity is to relentlessly focus on minimizing production losses, beginning with your largest sources of loss. In other words, focus your attention on the smallest set of improvement actions that will yield big results.

Using a Top Losses report is particularly effective for stabilizing problematic areas of production. It leverages the principles of Agile: short cycles of work, coupled with frequent delivery of results, driving continuous improvement.

Production loss analysis is a cyclical process with three phases in each cycle:

- Track: Capture accurate Top Loss information

- Pick: Select actions based on the Top Losses

- Fix: Implement improvement actions

1. Track

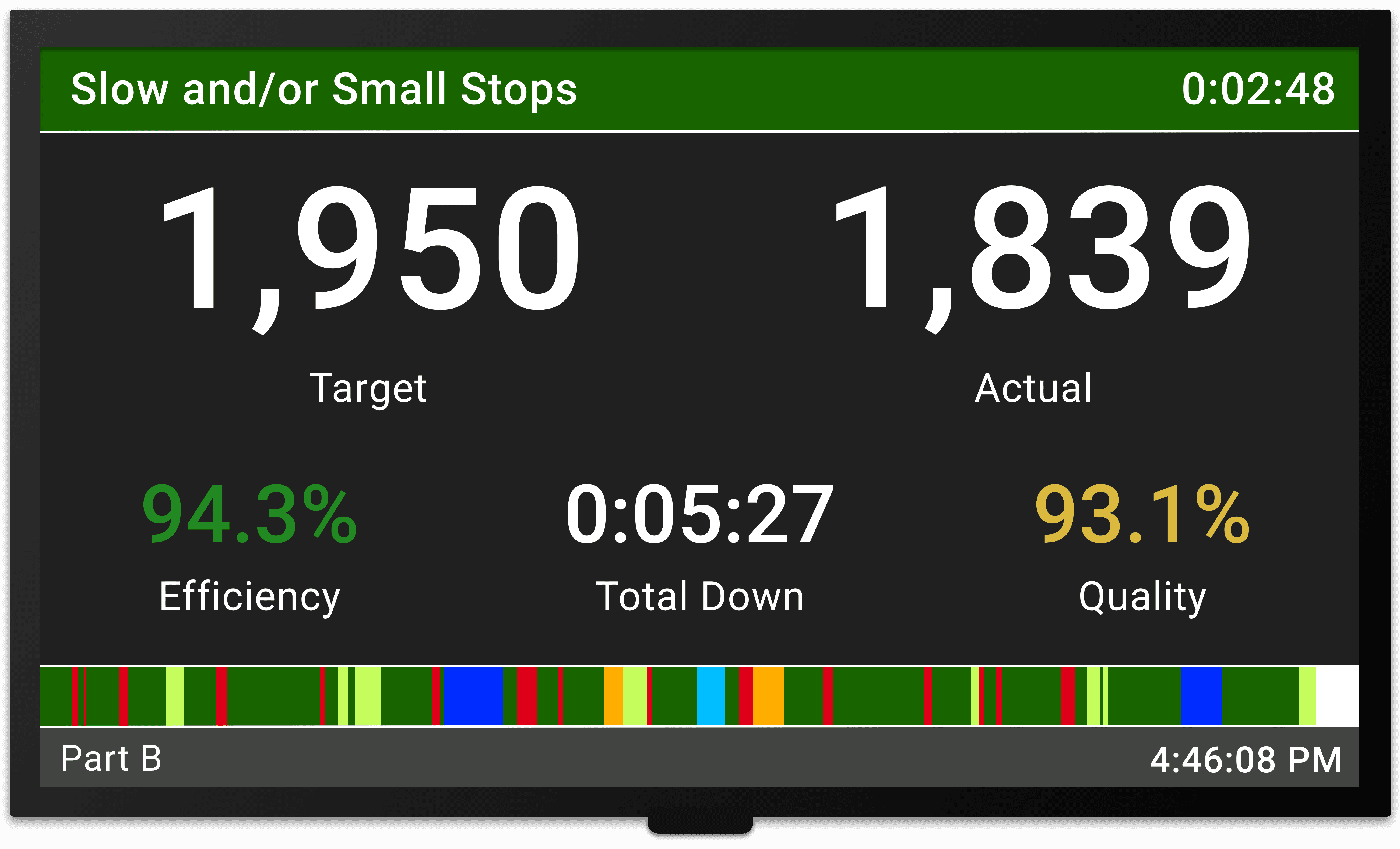

Every manufacturing company tracks what they've made (e.g., pieces, cases, or pallets), but few accurately track what they've lost – productive time. To improve manufacturing productivity, the goal of the ‘Track’ phase is to accurately capture all of the losses to perfect production (perfect production is manufacturing only good parts, as fast as possible, with no down time).

OEE and the Six Big Losses are excellent starting points for tracking production losses, and are natural companions to a Top Losses initiative. The key addition for Top Losses is that it is absolutely critical to capture loss reasons (particularly for down time).

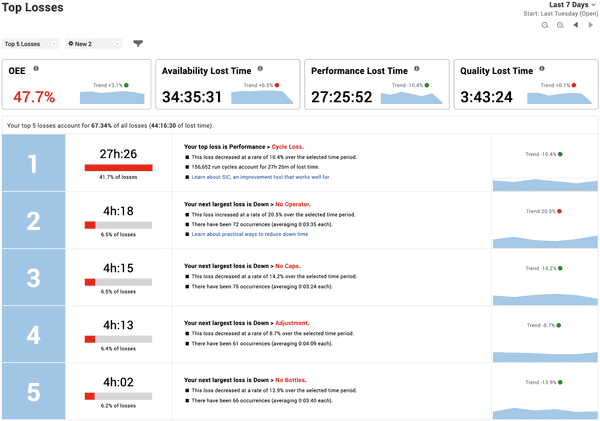

2. Pick

The ‘Pick’ phase is a meeting where the team reviews Top Losses, selects the next loss to be addressed, and agrees on specific improvement actions. A good starting point is to select the largest production loss where: your team has ideas on actions that they can take, minimal external resources are required, and actions can be taken straight away. The characteristics of an effective ‘Pick’ meeting are:

- Brief: Typically 30 minutes or less

- Positive: High energy and action-oriented

- Focused: Set agenda; finishes on time with specific actions selected

- Small: Attended primarily by people who will implement actions

3. Fix

'Fix' is the part that teams usually enjoy the most – taking action. It's important to maintain discipline to stay focused on the agreed loss, and to ensure that actions are completed before the next meeting. An excellent framework for monitoring the effectiveness of actions and making mid-course adjustments is Short Interval Control (SIC). Over time, introduce new tools to the team to increase the team's effectiveness in addressing and mitigating losses.

It is also important to celebrate success in order to reinforce the desired outcome (improved productivity). Reward success with recognition. For example, this can be as simple as free lunches for teams that generate notable improvements.

Benefits of Top Losses and Production Loss Analysis

In the short term, Top Losses harnesses the power of focus (fix one thing at a time) and prioritization (address the biggest losses first) to deliver fast improvements in productivity.

In the long term, Top Losses builds a foundation for accurately capturing loss information and instills the habit of basing actions on concrete information.

Team Member Roles

Top Losses production analysis involves the following roles:

| Role | Responsibilities |

|---|---|

| Manager | Initiate project. Define scope. Define the ‘Track’, ‘Pick’ and ‘Fix’ processes. Run the first meetings. Train supervisors. Audit and coach meetings to improve the process. |

| Supervisor | Ensure production loss data is accurate. Run ongoing ‘Pick’ meetings. Help the team implement improvement actions. Reinforce focus daily. Train team on new improvement tools. |

| Operator | Capture loss data and reason codes. Implement improvement actions. Share best practices with other teams. |

Key Insights for Top Losses

Capture Reasons

A truly effective Top Losses process is built on a foundation of accurate and insightful information. One of the most important characteristics of this information is the breakdown of all non-productive time into reasons.

Reasons can be captured manually by an operator or with the assistance of a system. Either way, the key is simplicity. It's much better to collect fewer reasons well than many reasons poorly. Reasons should be:

| Guideline | Description |

|---|---|

| Simple | Most companies use far too many reasons. Aim to capture the 20% of reasons that account for 80% of lost time. Use an “All Other Losses” reason for what's left. Typically, 20 or 30 reasons is sufficient. |

| Accurate | Make it very easy to record reasons (barcode scanning is often an effective solution). Make each reason very clear (especially when listed with other reasons). |

| Insightful | Periodically (e.g., monthly) review reasons. Remove reasons that aren't regularly used and add reasons as needed to ensure that ‘All Other Losses’ does not show up as a top 10 loss. |

Use Sparklines

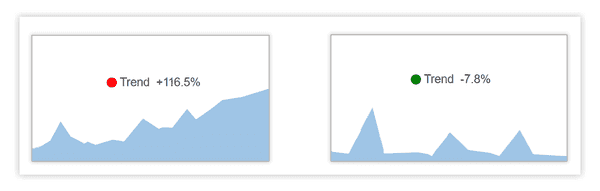

Sparklines are miniature graphs that convey information at a glance. For Top Losses, they show two particularly important aspects of a loss:

- Trend: Is the loss improving or getting worse? If the topmost loss is improving and the second most loss is getting worse, it may be better to focus on the second most loss.

- Pattern: Are there patterns in the loss? For example, infrequent large breakdowns versus consistent small losses.

Focus on Hard Data and Actions

It is very common and quite easy for people to shortcut “hard data” and instead base their actions on perception and gut feel. This can waste valuable time during ‘Pick’ meetings, because the focus is on justifying choices rather than setting actions.

When discussing losses, avoid blame (whose fault it is) and excuses (why nothing can be done). Instead, aim to spend 20% of the meeting reviewing data (to identify the focus area), 60% of the meeting brainstorming (to identify improvement actions), and 20% of the meeting planning (to set tasks and accountability).

Implement Effective Actions

It is useful to consider four types of Top Loss actions:

- Information: Improve the quality of information or gather more information to better understand the loss

- Process: Improve processes in a way that will mitigate the loss; e.g., create Standardized Work or develop skills through training

- Quick Fix: Implement a short-term or temporary fix; sometimes referred to as ‘fire-fighting’

- Forever Fix: Permanently improve the process so the problem is not likely to recur; sometimes referred to as a ‘100-year fix’

In the short term, focus on the type of action that will provide the biggest immediate benefit. In the long term, strive to achieve a mix of all four types of actions for a balanced improvement process.

Build a Sustainable Process

An important role of effective Leadership is to ensure that improvements are sustained. This is typically achieved through training, coaching, and governance (auditing). Some simple examples are:

- Regularly (weekly) recognize significant accomplishments

- Occasionally (monthly) join a ‘Pick’ meeting to demonstrate support, review actions, coach the team, etc.

- Periodically (quarterly) audit the accuracy of Top Loss information

Level and Difficulty

The Level is Foundation. Top Losses is one of the best ways for companies that are struggling with improvement initiatives to make significant progress in a short time frame.

The Difficulty is Easy. Top Losses is a very straightforward process. The most important elements are to ensure ‘Track’ data is accurate, ‘Pick’ meetings are effective, and ‘Fix’ actions are relevant and timely.

Rate Yourself on Production Loss Analysis

How good is your site at Top Losses? Answer ten simple questions to see how close you are to a model Top Losses implementation.

| Question | ✔ |

|---|---|

| 1. Are losses accurately tracked (and periodically audited)? | |

| 2. Are reasons assigned to all Down Time events? | |

| 3. Are reasons simple, accurate, and insightful? | |

| 4. Is �‘All Other Losses’ outside of the top 10 losses? | |

| 5. Is there a regularly scheduled ‘Pick’ meeting? | |

| 6. Is the ‘Pick’ meeting brief, positive, focused, and small? | |

| 7. Does each ‘Pick’ meeting result in a specific set of ‘Fix’ actions? | |

| 8. Are ‘Fix’ actions documented and tracked for effectiveness? | |

| 9. Do higher-level managers periodically join ‘Pick’ meetings? | |

| 10. Is there a structure for introducing new improvement tools? |

Comments or Questions?

We welcome your comments and questions. Contact us at: info@vorne.com.