Single-Minute Exchange of Die (SMED)

What Is Single-Minute Exchange of Die (SMED)?

Single-Minute Exchange of Die (SMED) is a collection of techniques for dramatically reducing the time it takes to complete a changeover. SMED was first developed by Shigeo Shingo, a Japanese industrial engineer, whose pioneering work reduced changeover times by a factor of 20 across a wide range of manufacturing companies. How did he achieve this? Consider the process of changing a tire:

- For many people, it can easily take 15 minutes to change one tire.

- For a NASCAR pit crew, it takes under 15 seconds to change four tires.

Many techniques used by NASCAR pit crews are similar to techniques used in SMED (e.g., perform as many steps as possible before the pit stop begins, use a coordinated team to perform multiple steps in parallel, and create a highly optimized and standardized process).

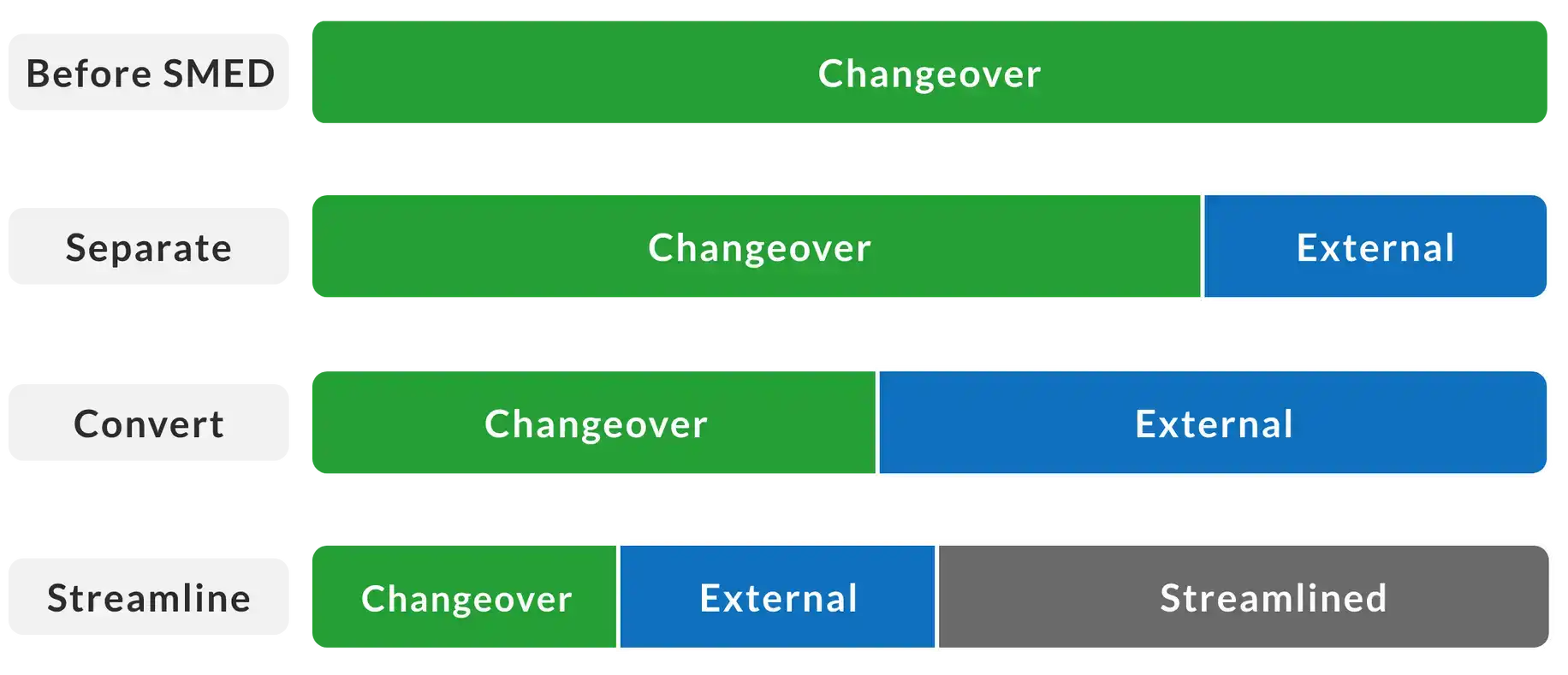

In SMED, the changeover process is broken into a sequenced list of steps called elements. The essence of SMED is to convert as many elements as possible to “external” (performed while the equipment is running), and to remove or streamline the remaining elements.

Conceptual SMED Stages

Separate

In this stage, elements that can be performed with little or no change while the equipment is running are identified and moved “external” to the changeover (i.e., performed before or after the changeover). This stage is fertile ground for quick wins.

Examples of elements that may be able to be separated include retrieving tools, materials, or instructions before the changeover; performing cleaning tasks external to the changeover; and performing final quality checks for prior production external to the changeover.

Convert

In this stage, remaining elements are examined to determine if they can be modified in some way to be external, or if they can be eliminated. The result is a list of candidates for further action. This list should be prioritized so the most promising candidates (i.e., the ones with the best cost/benefit ratio) are acted on first.

Examples of converting techniques include preparing parts in advance (e.g., preheating dies); using duplicate jigs to perform alignment and other adjustments before the changeover; modularizing equipment (quick changing a pre-prepared modular part instead of adjusting a fixed part); and modifying equipment (e.g., add guarding to enable safe cleaning while running).

Streamline

In this stage, the remaining elements are reviewed with an eye towards simplifying or changing them so they can be completed in less time. Top priority should go to internal elements to support the primary goal of shortening the changeover time. As in the previous stage, a simple cost/benefit analysis should be used to prioritize actions.

Examples of streamlining techniques include eliminating bolts in favor of quick release mechanisms; eliminating adjustments in favor of standardized settings; eliminating motion by reorganizing the workspace; using mobile racks to quickly provide access to tools and parts; and creating parallel operations with multiple team members (paying close attention to safety issues).

Benefits Of SMED

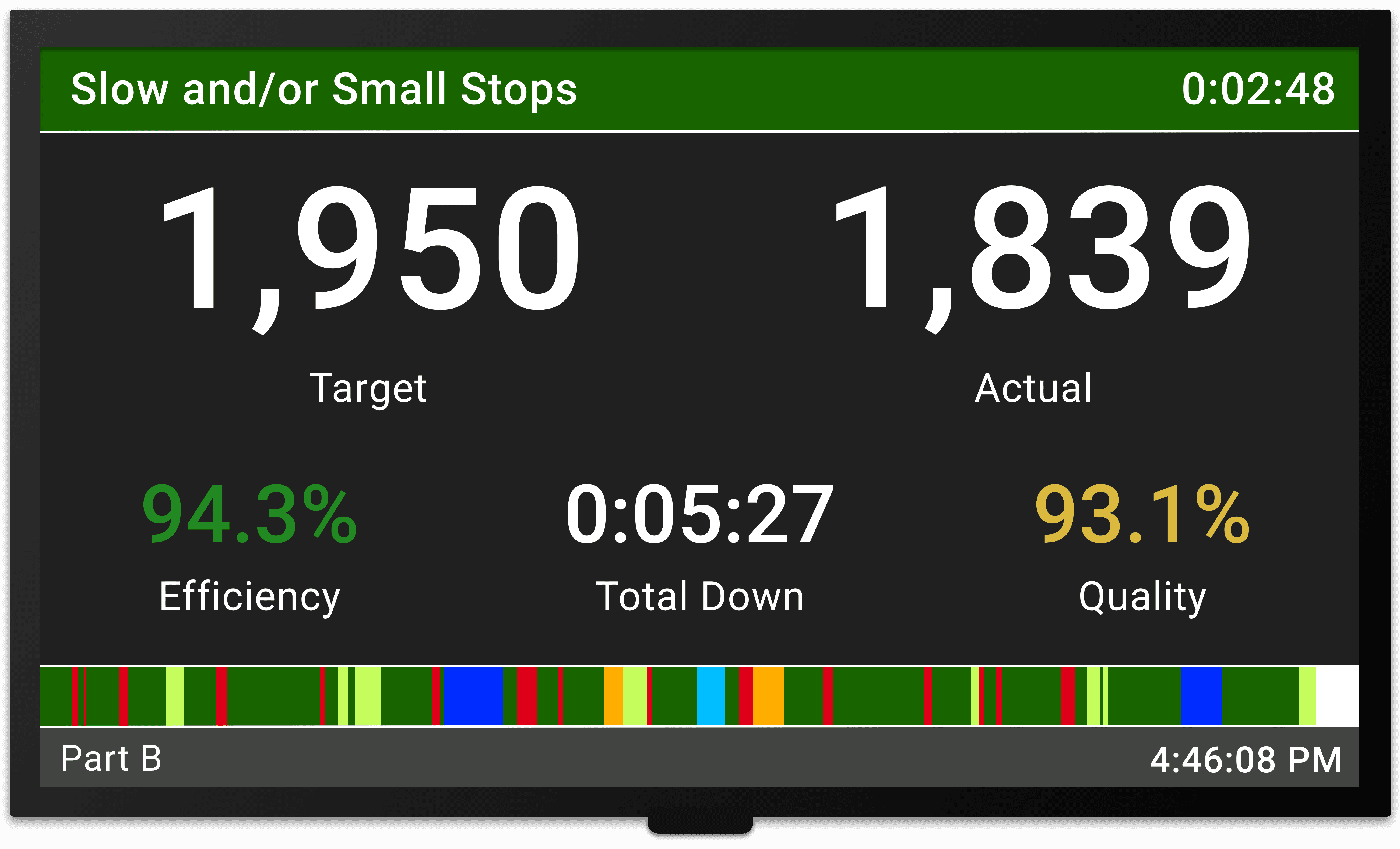

In the short term, SMED lowers manufacturing cost by reducing downtime and providing smoother startups (both of which improve OEE).

In the long term, SMED enables smaller lot sizes, improved responsiveness to customer demand, and lower WIP (work in progress) and inventory levels.

Team Member Roles

SMED involves the following roles:

| Role | Description |

|---|---|

| Manager | Initiate project. Define scope. Pick implementation team. Schedule time (and stock cover) for completing the process. Set and track improvement targets. Arrange for training resources. Audit process implementation. |

| Supervisor | Run SMED workshops. Manage SMED stages and passes. Lead brainstorming sessions. Ensure standard work instructions are created and followed. Audit changeovers. |

| Operator | Prepare and carry out changeovers with work instructions. Identify improvements. Cross-train improvements across the team. |

Key Insights of SMED

Select a Pilot Area

Spending time to select the optimal target area for your pilot SMED program will improve the odds of a successful outcome. Teams often pick the process with the longest changeover. Instead, look for a process with the following characteristics:

- The changeover is short enough to fully grasp and long enough to have significant room for improvement (e.g., 30 to 60 minutes)

- There are large variations in changeover times (usually this indicates excellent potential for improvement)

- There are multiple opportunities to perform the changeover each week (so proposed improvements can be quickly tested)

- Employees in the prospective pilot area are engaged and motivated (enthusiasm and a desire to succeed are important enablers)

- Success will Improve the Constraint (bringing immediate, bottom-line benefits)

Start With a Meaningful Baseline

Explicitly define how to measure the length of changeovers to ensure they are measured consistently. For example: “Changeover time is measured from the last good part of the previous job at normal production speed, to the first good part of the next job at normal production speed.”

Once you have a clear definition, capture a baseline time. A simple way to do this is to video a “normal” changeover. This video can also be used to create the initial list of SMED elements. Be aware of the “Hawthorne Effect” – changeover times may temporarily improve as a simple result of observing the process.

Question Everything

There is tremendous power in assuming that any problem is solvable. The most effective SMED teams presuppose that every element can be made external – they just need to find the best way. The following questions help reinforce this way of thinking:

| Stage | Question |

|---|---|

| Separate | Can this element, as currently performed or with minimal change, be completed while the equipment is running? |

| Convert | If there was a way to make this element external to the changeover what would it be? How could we do it? |

| Streamline | How can this element be completed in less time? How can we simplify this element? |

Capture Best Practices as Standardized Work

Companies are sometimes concerned that SMED will cause operators to rush through changeovers, compromising quality or safety. In practice, an effective SMED program captures best practices as Standardized Work, which is integral to repeatability, quality, and safety. Make sure to have a process for keeping work instructions up-to-date (as living documents) and disseminated (through training).

A nice byproduct of SMED and standardized work is that it helps ensure the startup phase of manufacturing after a changeover is free of the defects and downtime that are often associated with startup.

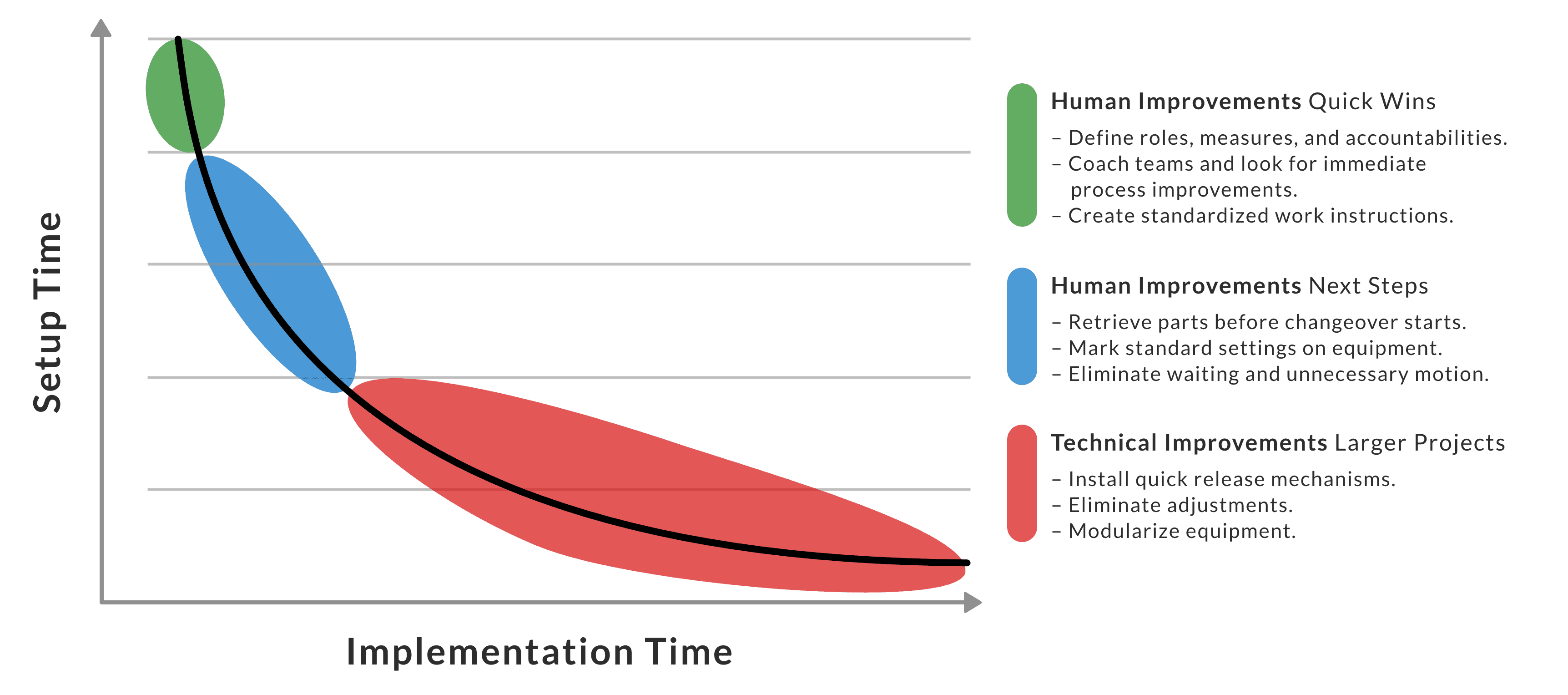

Focus First on “Human” Improvements

When implementing SMED it is useful to consider two broad categories of improvement:

- Human: Achieved through preparation and organization

- Technical: Achieved through engineering and optimization

Human improvements are typically faster and less expensive than technical improvements. In other words, quick wins and the fastest progress usually come from human improvements.

Level and Difficulty

The Level is Intermediate. SMED is broadly accepted as a best practice for reducing changeover times; however, changeover time may not be the most significant and urgent loss for your company.

The Difficulty is Moderate. The overall concepts are straightforward, but there are a significant number of details in underlying techniques.

Rate Yourself on SMED

How good is your site at SMED? Answer ten simple questions to see how close you are to a model SMED implementation.

| Question | ✔ |

|---|---|

| 1. Is a baseline time established for each changeover? | |

| 2. Is a baseline list of elements created for each changeover? | |

| 3. Is each and every element thoroughly reviewed and questioned? | |

| 4. Are there distinct stages for Separate, Convert, and Streamline? | |

| 5. Is there an explicit goal (e.g., 50% time reduction) for each cycle? | |

| 6. Are best practices captured as standardized work instructions? | |

| 7. Are standardized work instructions regularly reviewed for updates? | |

| 8. Are all shifts trained and coached on work instructions? | |

| 9. Are changeovers completed with ±10% consistency? | |

| 10. Are changeovers completed in under 10 minutes? |

Comments or Questions?

We welcome your comments and questions. Contact us at: info@vorne.com.