XL HD+

The Most Cost-Effective Way to Monitor Production

The XL HD+ Productivity Appliance is a purpose-built edge computing device designed and manufactured by Vorne to monitor production, accelerate your digital transformation, and foster a culture of productivity.

Try XL HD+ Free for 90 Days

Small Footprint, Huge Impact

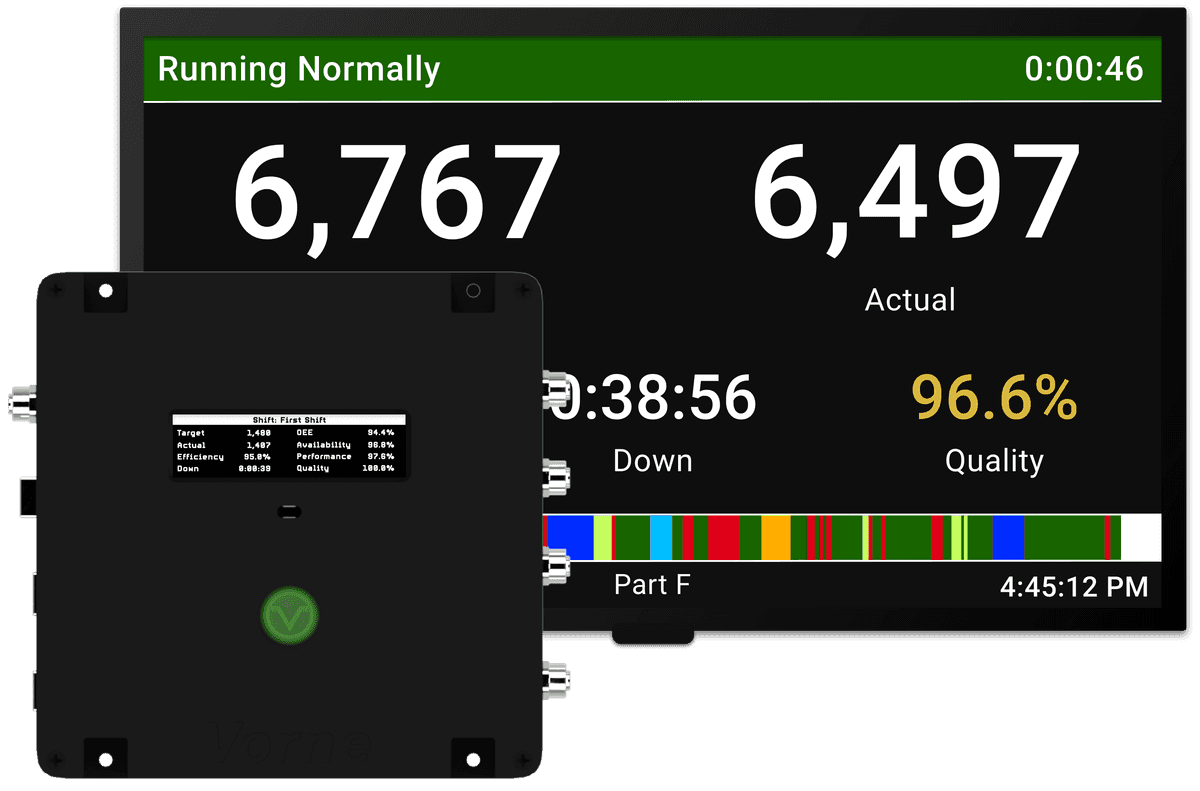

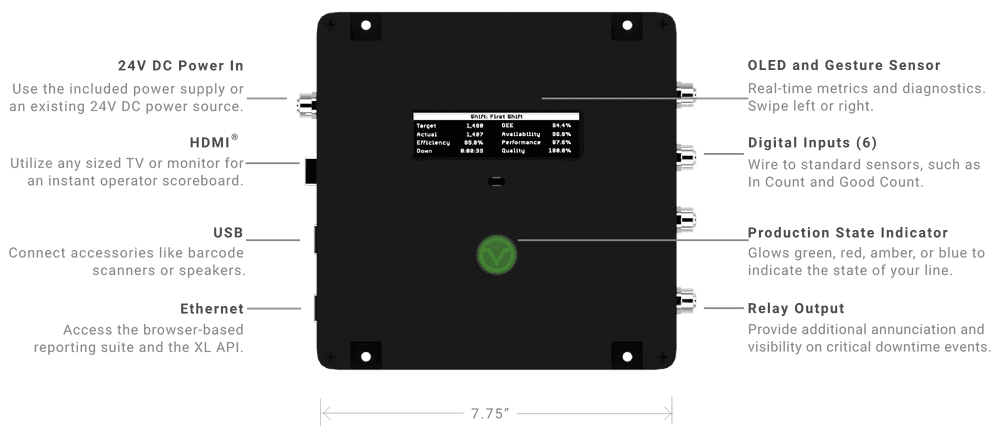

XL HD+ is a compact, rugged, industrial device that fully integrates hardware and software to deliver production monitoring in real time. Simply connect power plus one or two sensors, and XL instantly delivers 140+ metrics across 20+ data dimensions, all easily accessible through its extensive and intuitive browser-based reporting suite. Connect a TV or monitor of your choice via HDMI for an operator scoreboard that further aligns your entire team with a shared view of operations.

Built on our next-generation hardware platform with significantly greater processing power, memory, and storage, XL HD+ is well equipped to handle today’s challenges and tomorrow’s innovations.

The Price: $4,690

- No hidden fees

- No recurring fees

- No maintenance fees

- No contracts to sign

- No custom software

- One-time cost

- Unlimited users

- Free software updates

- Free technical support

- 3-year warranty

The XL HD+ is $4,690 per line (USA and Canada). Quantity discounts are available.

Visualize Your Plant Floor

Hit Your Target, Win the Shift

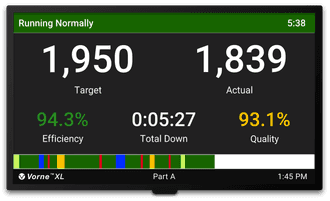

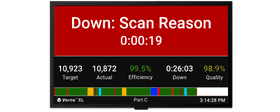

Connect any size TV or monitor to the XL HD+ HDMI port for an instant operator scoreboard. For example, a 55" display can show metrics as large as 5" for easy viewing at 100+ feet.

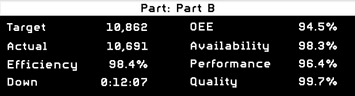

The plant-floor scoreboard is the single most impactful and quickest way to drive improvement - by empowering and encouraging your operators to win the shift. Empower operators with the KPIs most relevant to them. Encourage operators with an efficiency score - a clear, easily understandable takt-based target with a pace that automatically adjusts based on the part you’re running. An Efficiency score of 100% or better means they’re winning the shift.

For plant-floor supervisors, the integrated chronogram is particularly helpful, as it provides an instant visualization of the shift. They can easily identify down time at the start or end of the shift, running slowly after changeovers, etc.

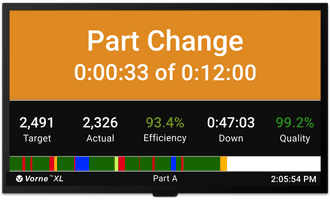

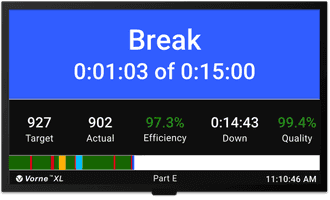

The scoreboard automatically adapts based on the production state XL detects - showing the right information at the right time. When your process is running, the scoreboard shows the current state of the line at a glance.

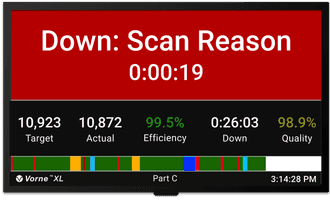

When your process is not running, the focus is on helping you return to production. XL automatically detects and displays unplanned events (such as running slowly and down) and also indicates planned events (such as changeovers and breaks) with clear, attention-grabbing visuals.

Operators: Win the Shift

Operational Tools for Your Plant-Floor Team

XL automatically collects precise data about down time, rejects, etc. so that all operators need to do is annotate this data with their perspective (e.g., add reasons for down events). The plant-floor scoreboard relfects the real-time status of the line, alerting operators when appropriate and keeping them informed.

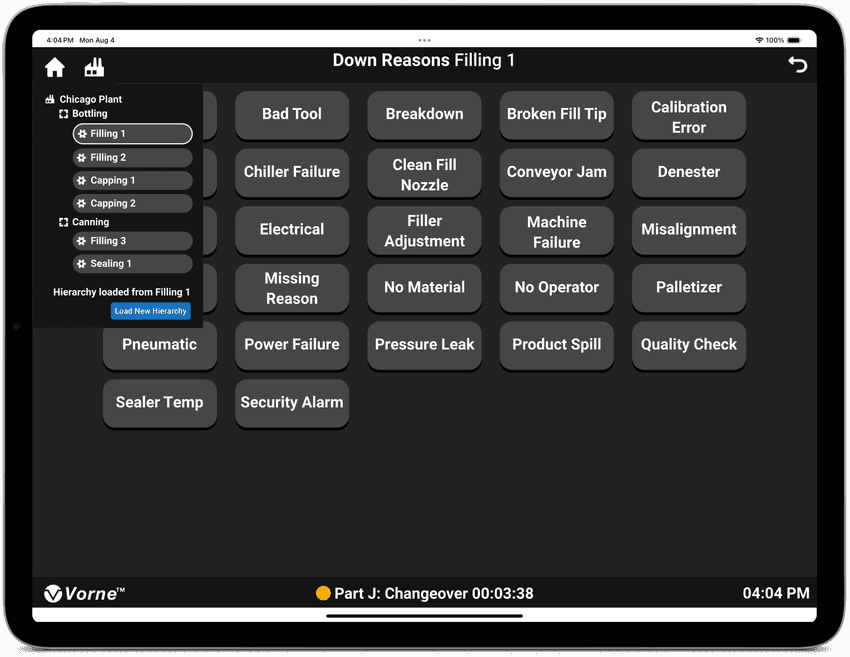

When the line goes down, operators are prompted to add a reason, which they can do quickly and easily with a barcode scanner or with the free XL Sidekick app. Operators add their perspective in real time, right at the source, and right when it is fresh in their minds.

Supervisors: A Continuous Improvement Roadmap

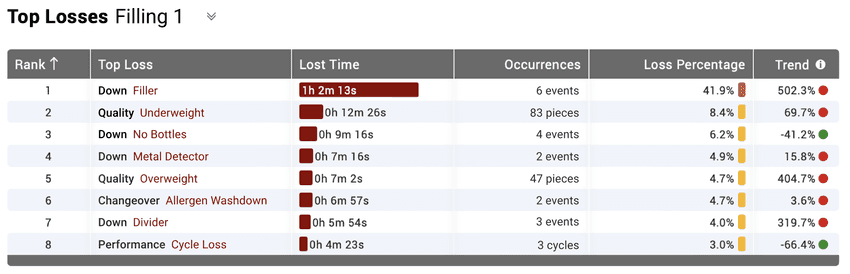

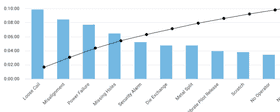

Top Loss Reports for Tactical Quick Wins

One of the fastest ways for supervisors to impact manufacturing productivity is to relentlessly focus on production losses, beginning with the largest sources of loss. In other words, focus your attention on the smallest set of improvement actions that will yield big results. Think of the browser-based Top Losses report as your real-time, personalized continuous improvement roadmap.

Other popular tools for supervisors include:

- Down Time Pareto (an all-time classic)

- TPT (the Total Production Timeline combines a colorful chronogram with categorized loss data)

- Six Big Losses (transforms OEE into six distinct categories that are natural targets for improvement actions)

- Hour-by-Hour Heatmap (even better when stacked with a chronogram showing breaks, changeovers, etc.)

Managers: The Big Picture

Strategic Decisions Based on Precise Data

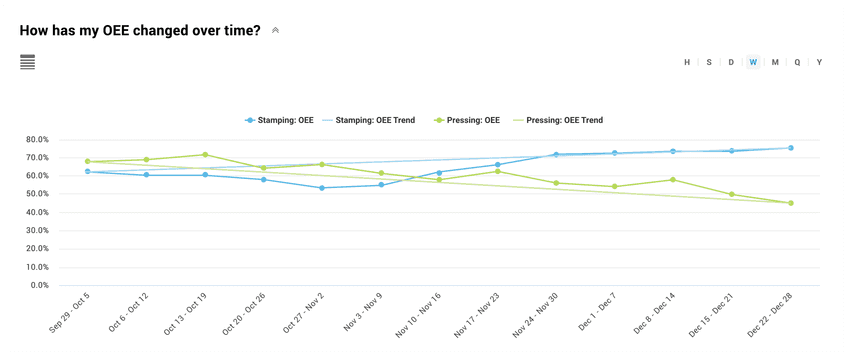

Having an accurate view of production throughout the entire enterprise aids managers in setting and following up on large-scale objectives. Data rollup and trended reports inform long term goals that then guide tactical and operational actions.

Charts depicting data over time, like this example that plots quarterly OEE trends by department, reveal challenge areas and areas that deserve praise because they are exceeding targets. In this case, both Stamping and Pressing began the quarter in decline. However, Stamping began steady improvement a few weeks in, whereas Pressing continued to decline. The manager can dig deeper to find out what each department did differently, and set appropriate goals for the next quarter.

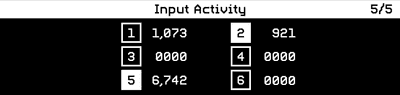

Wave Hello

Navigate between screens directly on the XL HD+ device using the built-in gesture sensor - simply swipe left or right. Operators can view real-time metrics for the current shift, part, and production events - or access diagnostic screens for device details like input activity and system status - directly from the device.

Metric

Diagnostic

Welcome to the XL Platform

Your XL Device Is Just the Beginning

XL devices are the foundation of the XL platform, which is a seamlessly connected system designed around three pillars: production monitoring, digital transformation, and culture of productivity. These pillars have one focus and one goal: rapid and sustainable improvements in manufacturing productivity.

XL serves as a single source of accurate and actionable data and insights. And as your needs grow, the XL platform grows with you - without lengthy projects, custom development, or needless complexity.

Built-In Reports

XL HD+'s powerful integrated reporting suite has over 60 built-in reports.

Custom Reports

Craft any number of custom reports using drag-and-drop widgets.

Integrate With Ease

Integrate to PLCs, MES, and ERP with the XL API or prebuilt partner solutions.

Alerts and Emails

Subscribe to alerts (e.g., line down) and reports (e.g., shift, daily, weekly).

XL Sidekick

Instantly access every XL in your plant from a tablet or phone with our free app.

Line Status At-a-Glance

Empower operators to course correct with contextual real-time data.

Evaluate XL HD+ in your production environment with full platform access.

Start Your Free 90-Day TrialTechnical Specifications

Processing Core

(4) 64-bit, 1.4 GHz ARM A-53 Cores

40GB Flash Memory, 4 GB RAM

Communication Ports

(1) 10/100 Auto-MDIX, Ethernet

(1) 2.0 USB-A Host, 500mA 5 VDC

(1) HDMI 1.4

Environmental

0° to 50°C ambient

5% to 95% humidity (non-condensing)

Digital Inputs and Outputs

(6) 5 to 24 VDC, Sink or Source

(1) SPDT, 30 VDC at 1A, Relay Out

Dimensions and Weight

7.75 x 7.75 x 2.00 in | 3 lbs

Power

24 VDC, 24 W