Medical Device Manufacturing

Medical device manufacturers work within a highly regulated environment while also facing the challenges inherent in producing precision products with very strict tolerances and specifications, often in clean room environments. At the same time, medical device manufacturers are not immune to the necessity of keeping a close eye on operational margins and profitability. That is why Vorne XL is a very popular tool for this industry.

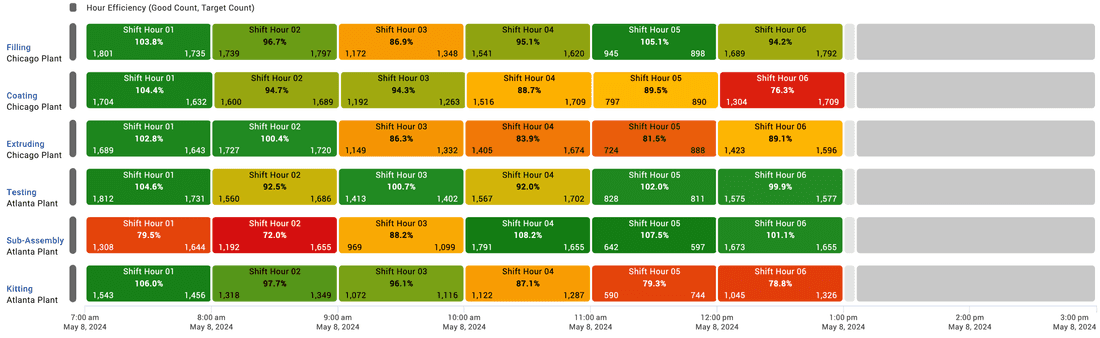

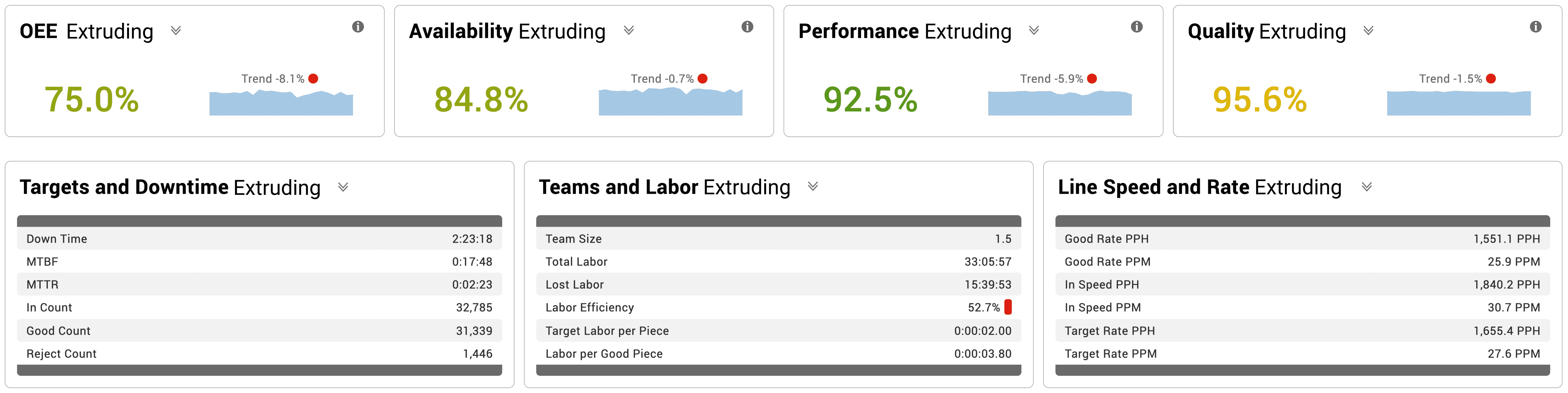

XL drops onto your existing process with little to no changes to that process. Whether you operate automated vial filling and dosing lines, semi-automated needle and syringe machines, manual sub-assembly and box build processes, or anything in between, Vorne XL captures comprehensive OEE, Six Big Loss, and TEEP data. It accounts for every source of lost production time and opportunity and delivers plant-wide visibility of real-time data and historical analytics. Operators benefit as well with contextual scoreboards that show them the state of the process and whether they are on track to “win” the shift.

Vorne XL moves medical device operations far beyond manual data capture to deliver critical insights for driving process improvement and actualizing change with 100+ metrics and 20+ data dimensions. Other benefits of XL that customers love include no software to install, no servers to maintain, no recurring fees, and no contracts. Instead you get unlimited users, free technical support, a 3-year warranty, and free software updates. All in an inexpensive, off-the-shelf product.

Driving Improvement for Medical Devices

Our medical device customers strive to make something as close to perfect as possible, safe to use, and compliant with underlying regulations. It is critical to be able to optimize the process while maintaining the absolute product quality that their customers require.

The Vorne XL Productivity Appliance empowers medical device manufacturers to monitor their processes in real time, improve throughput, and maximize efficiency, all while preserving the integrity of their products. XL drops onto your existing process, making it a quick and easy solution that requires little to no changes on the line. This is a unique and critical advantage of Vorne XL.

Key Benefits for Medical Device Manufacturers

Vorne XL is completely agnostic to the type of equipment in your manufacturing process. This is a huge advantage as you can easily apply XL to any process and get the same deep wealth of information. XL includes I/O to integrate with your process, a scoreboard for your operators, and built-in reporting for your managers. Even better, it easily and incrementally scales from machine to enterprise. Monitor your fillers, extruders, grinders, coaters, testers, sub-assembly and kitting lines, or other equipment with one solution, quickly seeing benefits such as:

- 1Data Anywhere, Data Everywhere Limited access to areas such as clean rooms makes it challenging to get the right information in front of the right individuals. With XL’s embedded web interface, it’s easy to view production data remotely so your whole team can understand how the process is running in real time.

- 2Flexible Inputs Leverage existing sensors such as photo-eyes, proximity switches, or relays, which can be used without impacting your machines or processes, bypassing any need to change your PLC coding.

- 3Configurable Reporting In addition to our robust built-in reports, leverage highly configurable custom reporting to provide the exact context and analysis you need to succeed.

- 4Automated Alerts Automated text and email alerts enable you to push and escalate notifications to the appropriate individuals when they need it, where they need it.

- 5Universal OEE Capture Availability, Performance, and Quality for each asset on the plant floor, enabling you to seamlessly compare processes, visualize losses, and optimize the scheduling of production runs.

You're In Excellent Company

Vorne XL customers span across 45+ countries and are in virtually every industry - including many in medical device manufacturing. Take a look at a sampling of medical device manufacturers that have unlocked the benefits of XL to obtain accurate and actionable data, critical insights, and a foundation for their continuous improvement programs.

Learn More About Vorne XL

We would be happy to show you XL, deep dive into your challenges and your processes, and answer any questions you may have. We also offer free 90-day trials. In fact, we have completed thousands of successful XL trials. Did you know that 92.8% of companies that try XL buy XL?

Metrics, Dimensions, and Dashboards

Vorne XL provides you with an incredible data foundation and an outstanding suite of reporting tools to effectively drive your continuous improvement, lean manufacturing, and digital transformation initiatives. With XL you get immediate access to over 100 highly accurate and actionable metrics and 20 data dimensions - in real time and for deep retrospective analysis through historical reporting. There are dozens of built-in reports, and you can easily create your own reporting dashboards.

Vorne XL User Success Stories

XL helps manufacturers in almost every industry improve their process productivity. You will love our free support, free software updates, 3-year warranty, transparent pricing, fast implementation, and of course, the wealth of product features. That is why we have so many customers that share their success stories.

Medical Device Specialties

Our XL Productivity Appliance, with its fully integrated OEE reporting system, works well across an extremely broad range of medical device industry specialties. Here are some of the more common specialty areas where XL is used:

- Biopsy Devices

- Cardiovascular Devices

- Dental Equipment and Supplies

- Endoscopy Equipments

- Home Healthcare Devices

- Implantable Devices

- Infusion Pumps

- Laboratory Equipment

- Laser Therapy Equipment

- Medical Imaging Equipment

- Neurological Devices

- Ophthalmic Equipment

- Orthopedic Devices

- Prosthetic Devices

- Rehabilitation Equipment

- Respiratory Devices

- Surgical Instruments

- Telemedicine Devices

- Ultrasound Equipment

- Wound Care Products