Metal Stamping and Pressing Manufacturing

Metal stamping and pressing serves a vast range of other industries including aerospace, agriculture, automotive, construction, electronics, medical, military, and telecommunications, to name a few. How do manufacturers remain competitive in a market that requires both high volume and critically precise components for everything from swing sets to submarines? Continuous Improvement! There is a constant push toward internal process improvements, and even longstanding techniques like SMED (Single-Minute Exchange of Die) continue to be very relevant in the path to sustained profit margins.

Companies in the metal stamping industry often need to move large coils that weigh thousands of pounds, measure materials in tons, and somehow still cut out every possible second from the manufacturing process. As such, OEE is an important metric in the industry. Vorne XL moves stamping and pressing operations far beyond manual data capture to gain critical insights for effectively driving process improvement and actualizing change with 100+ metrics and 20+ data dimensions.

Other benefits of XL that customers love include no software to install, no servers to maintain, no recurring fees, and no contracts. Instead you get unlimited users, free technical support, a 3-year warranty, and free software updates. All in an inexpensive, off-the-shelf product.

Driving Improvement for Metal Stamping and Pressing

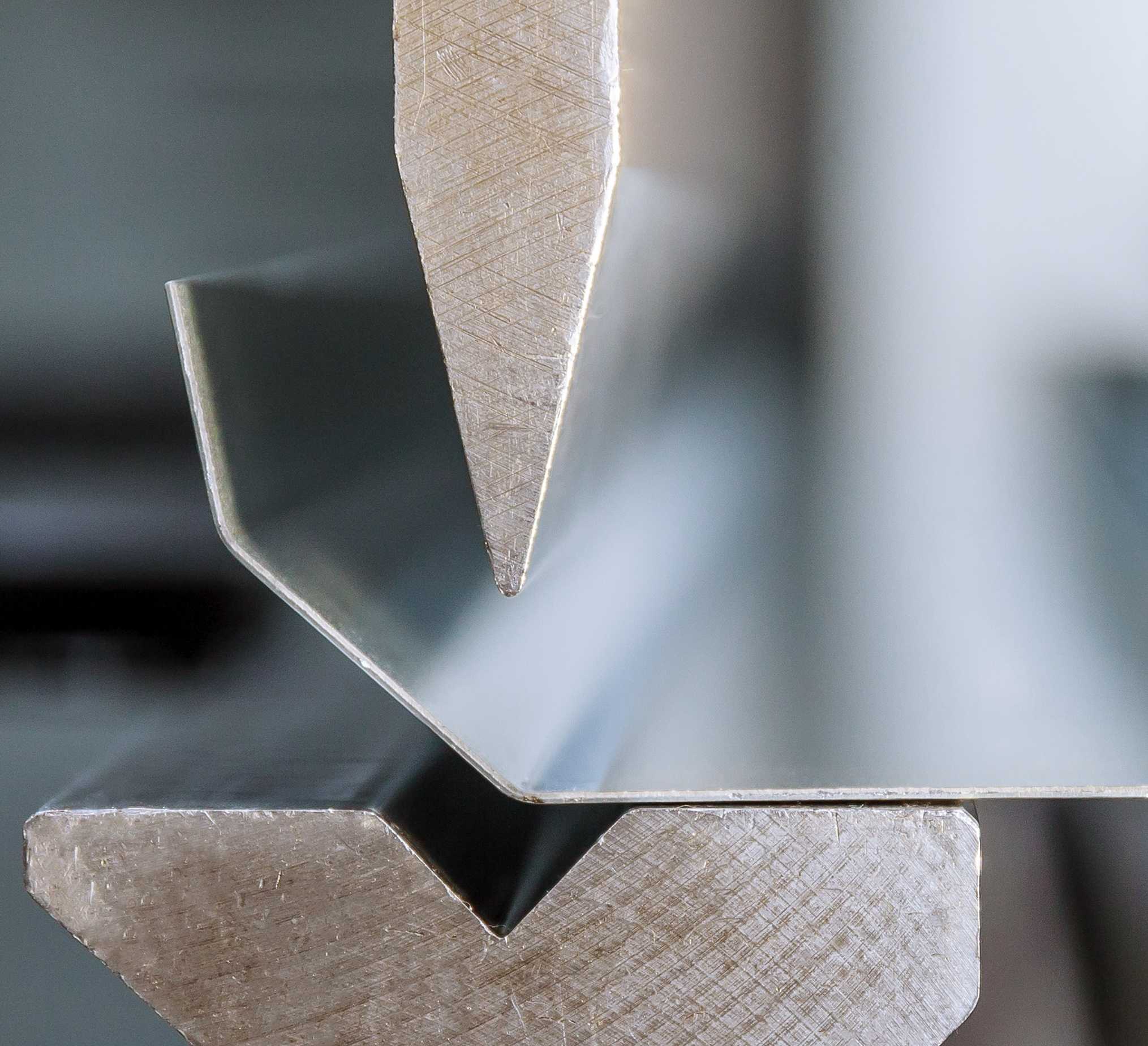

Our metal stamping and pressing customers strive to make something with tighter tolerances, greater durability, and less rework or scrap than other options on the market. It is critical to be able to optimize the process while maintaining the product that your customers want and need.

The Vorne XL Productivity Appliance empowers metal stamping and pressing manufacturers to monitor their processes, improve throughput, and maximize efficiency, all while preserving the integrity of their products. XL drops onto your existing process, making it a quick and easy solution that requires little to no changes on the line.

Key Benefits for Metal Stamping and Pressing

Vorne XL products are completely agnostic to the type of equipment in your manufacturing process. This is a huge advantage as you can easily apply XL to any equipment and get the same wealth of information. XL includes I/O to integrate with your process, a scoreboard for your operators, and built-in reporting for your managers. It easily scales from machine to enterprise. Monitor processes like blanking, embossing and coining on mechanical, hydraulic or servo presses, deep draw presses, press breaks or fin blanking lines, and many others with one solution, quickly seeing benefits such as:

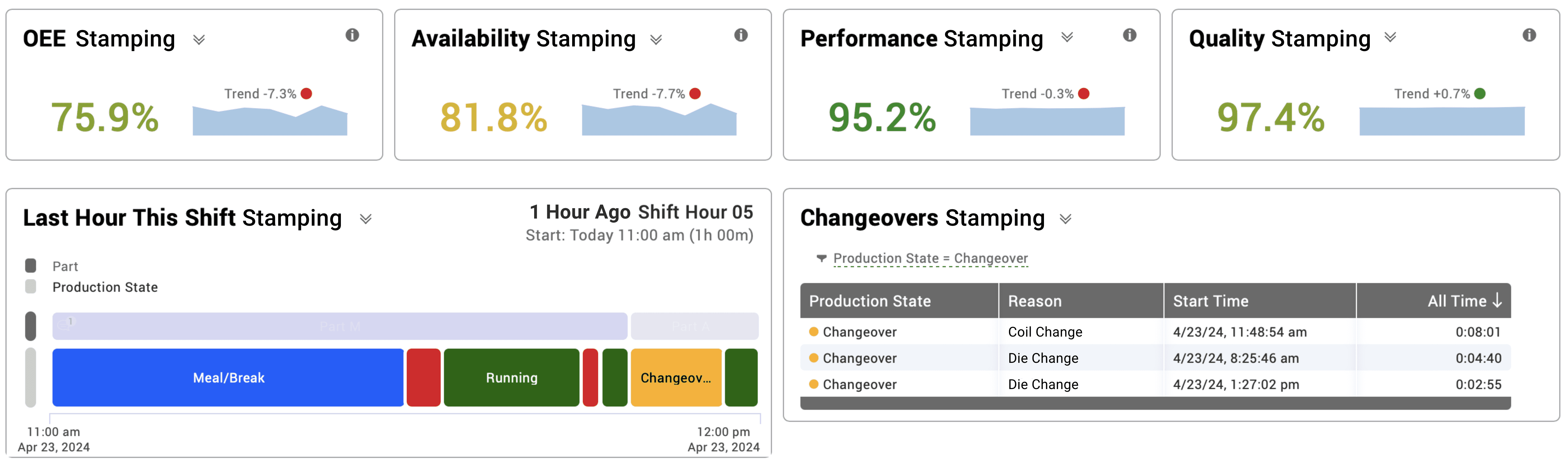

- 1Optimize Changeovers SMED has long been the gold standard for changeovers in the stamping industry. Let XL show you the fastest, slowest, and average coil changeover times, informing your team of aggressive but attainable targets.

- 2Easily Accessible Data Metal fabrication equipment is often inherently large and loud, making it difficult to convey production data on the plant floor without clearly visible KPIs. With Vorne XL’s integrated industrial plant floor scoreboards and detailed dashboards accessible over your network, you can easily manage every measured asset and identify issues in real time.

- 3Dimensional Data Stamping and pressing often require long production runs that span multiple shifts or even multiple days. Analyzing data by part, job, shift, or team over any period of time enables you to run comparative analyses or trend information over time to identify areas for improvement.

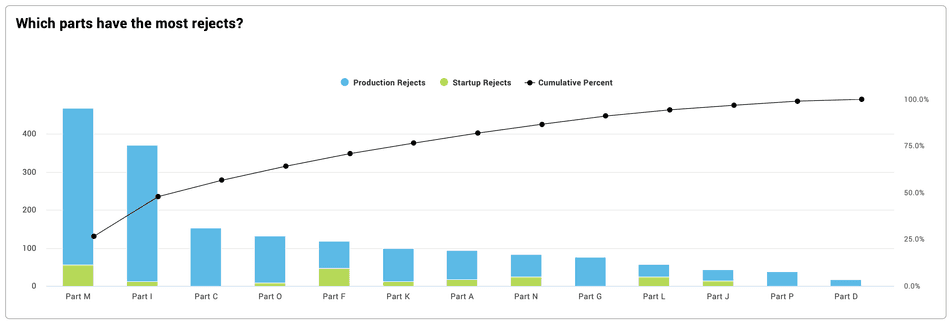

- 4Quality and Scrap Measurements Whether you manually track discrepant material or automate the trim or scrap produced, XL will provide insight into quality metrics such as quality loss percentage, rejects by reason, and quality lost time to quantify waste.

- 5Visual Timelines The ability to visually understand how your equipment transitionsbetween periods of run time (or running slow), unplanned downtime, coil changes or die changes, and even breaks, safety meetings, or startup events is critical to understanding where your production time is being allocated.

You're In Excellent Company

Vorne XL customers span across 45+ countries and are in virtually every industry - including many in metal stamping and pressing. Take a look at a sampling of manufacturers in your industry that have unlocked the benefits of XL to obtain accurate and actionable data, critical insights, and a foundation for their continuous improvement programs.

Learn More About Vorne XL

We would be happy to show you XL, deep dive into your challenges and your processes, and answer any questions you may have. We also offer free 90-day trials. In fact, we have completed thousands of successful XL trials. Did you know that 92.8% of companies that try XL buy XL?

Metrics, Dimensions, and Dashboards

Vorne XL delivers an incredible data foundation and the tools you need to effectively drive your continuous improvement, lean manufacturing, and digital transformation initiatives. With XL you get immediate access to over 100 highly accurate and actionable metrics and 20 data dimensions - in real time and for deep retrospective analysis through historical reporting. There are dozens of built-in reports and you can easily create your own reporting dashboards.

Vorne XL User Success Stories

XL helps manufacturers in almost every industry improve their process productivity. You will love our free support, free software updates, 3-year warranty, transparent pricing, fast implementation, and of course, the wealth of product features. That is why we have so many users who share their success stories.

Metal Stamping and Pressing Specialties

Our XL Productivity Appliance, with its fully integrated OEE reporting system, works well across an extremely broad range of metal stamping and pressing industry specialties. Here are some of the more common specialty areas where XL is used:

- Automated Stamping Equipment

- Blanking and Piercing

- Coil Feeding and Straightening

- Coil Processing

- Coil Slitting and Recoiling

- Die Cutting

- Die Maintenance and Changeovers

- Fine Blanking

- High-Speed Stamping Lines

- Inspection and Quality Control

- Integrated Stamping Lines

- Material Handling and Conveying

- Press Speed and Cycle Time Optimization

- Progressive Stamping

- Scrap Reduction

- Servo Press Applications

- Tooling Wear and Tear Monitoring

- Transfer Presses