Real-Time Production Monitoring for Pharmaceutical Manufacturing

Pharmaceutical manufacturing centers around products that must be created to exact specifications in a heavily regulated environment. In an industry challenged by high R&D costs, competition in the form of generics, and extreme time-to-market pressure, pharmaceutical companies need to optimize their internal manufacturing processes in order to help them remain competitive.

Vorne understands the complexities of bringing digital technology to the plant floor. Pharmaceutical companies must maintain qualified lines in controlled environments, which makes conveying real-time production data and goals a more significant challenge. Vorne XL alleviates many of these concerns by providing a monitoring solution external to the line that is easily accessible over your local area network, enabling supervisors and management alike to see the performance of areas that were previously not monitored.

Other benefits of XL that our pharmaceutical customers love include no software to install, no servers to maintain, no recurring fees, and no contracts. Instead you get unlimited users, free technical support, a 3-year warranty, and free software updates.

Driving OEE Improvement and More in Pharma Manufacturing

It is critical for pharmaceutical manufacturers to consistently, safely, and efficiently manufacture the products that their customers depend on while still being able to understand where there are opportunities for improving the throughput of existing manufacturing processes.

The Vorne XL Productivity Appliance empowers you to monitor your processes, improve throughput, and maximize efficiency, all while preserving the integrity of your products. XL drops onto your existing process, making it a quick and easy solution that requires little to no changes to your manufacturing process.

Key Benefits of Vorne XL for Pharmaceutical Lines

One of the greatest advantages of Vorne XL is that it deploys as a simple edge computing device. Whether you need to monitor processes involving liquid or powder encapsulation, coaters, tablet presses, blister packs, solid dose filling, pre-filled syringes, or aseptic filling lines, XL “bolts on” externally to your process, enabling remote monitoring without impacting the form or function of the process itself. This is an enormous benefit as you can easily apply XL to virtually any pharmaceutical process and get the same wealth of information, including:

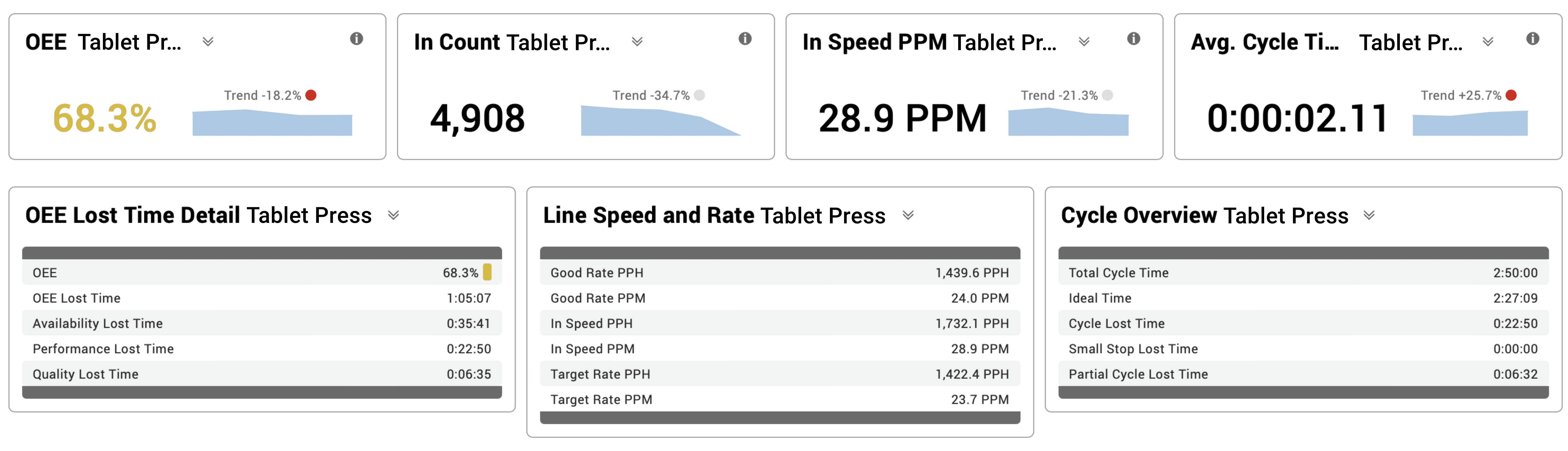

- 1Precise Cycle Times for High-Speed Operations Pharmaceutical manufacturing typically depends on high-speed operations (e.g., hundreds of pills per second moving through a tablet press). XL can easily handle hundreds of cycles per second - apply it to your high-speed lines with confidence.

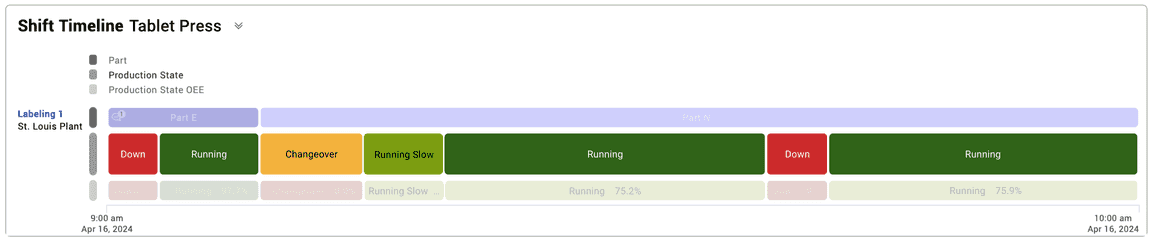

- 2Automatic Running Slow Detection Visualize periods of time during which the line runs slow, exposing potential performance loss trends following major or minor changeover events.

- 3Automated OEE Reporting Accurate, critical, and precise OEE calculation by the same passionate and knowledgeable experts who publish OEE.com.

- 4Customized Reporting Build upon an already robust reporting platform with intuitive custom reporting capabilities. Create reports and analyses that support your unique continuous improvement activities while easily integrating into your ERP or MES system.

- 5Scan Reasons Pareto your downtime simply by scanning a barcode to assign reasons. Capture all-important operator insights. Miss a reason? It is automatically highlighted in the timeline so you can see it and update it right away.

You're In Excellent Company

Vorne XL users span across 45+ countries and are in virtually every industry - including many in pharmaceutical. Take a look at a sampling of pharmaceutical manufacturers that have unlocked the benefits of XL to obtain accurate and actionable data, critical insights, and a foundation for their continuous improvement programs.

Learn More About Vorne XL

We would be happy to show you XL, deep dive into your challenges and your processes, and answer any questions you may have. We also offer free 90-day trials. In fact, we have completed thousands of successful XL trials. Did you know that 92.8% of companies that try XL buy XL?

Metrics, Dimensions, and Dashboards

Vorne XL delivers an incredible data foundation and the tools you need to effectively drive your continuous improvement, lean manufacturing, and digital transformation initiatives. With XL you get immediate access to over 100 highly accurate and actionable metrics and 20 data dimensions - in real time and for deep retrospective analysis through historical reporting. There are dozens of built-in reports and you can easily create your own reporting dashboards.

Vorne XL User Success Stories

XL helps manufacturers in almost every industry improve their process productivity. You will love our free support, free software updates, 3-year warranty, transparent pricing, fast implementation, and of course, the wealth of product features. That is why we have so many users who share their success stories.

We Support a Wide Range of Pharmaceutical Specialties

Our XL Productivity Appliance, with its fully integrated OEE reporting system, works well across an extremely broad range of pharmaceutical industry specialties. Here are some of the more common specialty areas where XL is used:

- Active Pharmaceutical Ingredients (APIs)

- Aseptic Fill-Finish Products

- Biopharmaceutical CDMOs

- Biosimilars

- Cellular Therapies

- Clinical Products

- Clinical Trial Materials

- Continuous Production

- Formulated Compounds

- Liquid Dosage Forms

- Nutraceuticals

- Over-the-Counter (OTC) Drugs

- Personalized Medicines

- Quality Control Labs

- Radiopharmaceuticals

- Regenerative Medicines

- Solid Dosage Forms

- Sterile Pharmaceuticals