Pulp and Paper Manufacturing

Pulp and paper manufacturers have an essential role in today’s economy, turning materials such as wood and recycled paper into the many cellulose-based products we rely on, such as paper, labels, and packaging. Converting, where paper is transformed into other products, is an area where automated production monitoring is particularly impactful. Many of the pulp and paper companies who benefit from utilizing the Vorne XL production monitoring system are converters, monitoring processes in which large rolls of material are turned into a broad range of finished goods (e.g., sheeted paper, filters, wet wipe packs, cardboard packaging, etc.).

Whether maintaining precise process speeds, reducing roll changeover and splicing times, or reducing scrap and trim, automated solutions such as Vorne XL provide a clear picture of production, accurately quantifying all sources of lost production time, and establishing a comprehensive data foundation for continuous improvement.

XL moves pulp and paper operations far beyond manual data capture to gain critical insights for driving process improvement and effectuating change with 100+ metrics and 20+ data dimensions including OEE, Six Big Losses, TEEP, and Labor Efficiency.

Other benefits of XL that our customers love include no software to install, no servers to maintain, no recurring fees, and no contracts. Instead you get unlimited users, free technical support, a 3-year warranty, and free software updates. All in an inexpensive, off-the-shelf product.

Driving Improvement for Pulp and Paper Manufacturing

Many of our pulp and paper customers have an added focus on sustainability while manufacturing a diverse range of products, cost effectively, and with an eye towards continuous improvement.

The Vorne XL Productivity Appliance empowers pulp and paper manufacturers to monitor their processes in real time, improve throughput, and maximize efficiency, all while preserving the integrity of their products. XL drops onto your existing process, making it a quick and easy solution that requires little to no changes on the manufacturing line. This is a unique and critical advantage of Vorne XL.

Key Benefits for Pulp and Paper Manufacturers

Vorne XL is completely agnostic to the type of equipment in your manufacturing process. This is a huge advantage as you can easily apply XL to any process and get the same deep wealth of information. XL includes I/O to integrate with your process, a scoreboard for your operators, and built-in reporting for your managers. Even better, it easily and incrementally scales from machine to enterprise.

Monitor your converting lines, rotary cutters or die cutters, and a variety of other equipment with one solution, quickly seeing benefits such as:

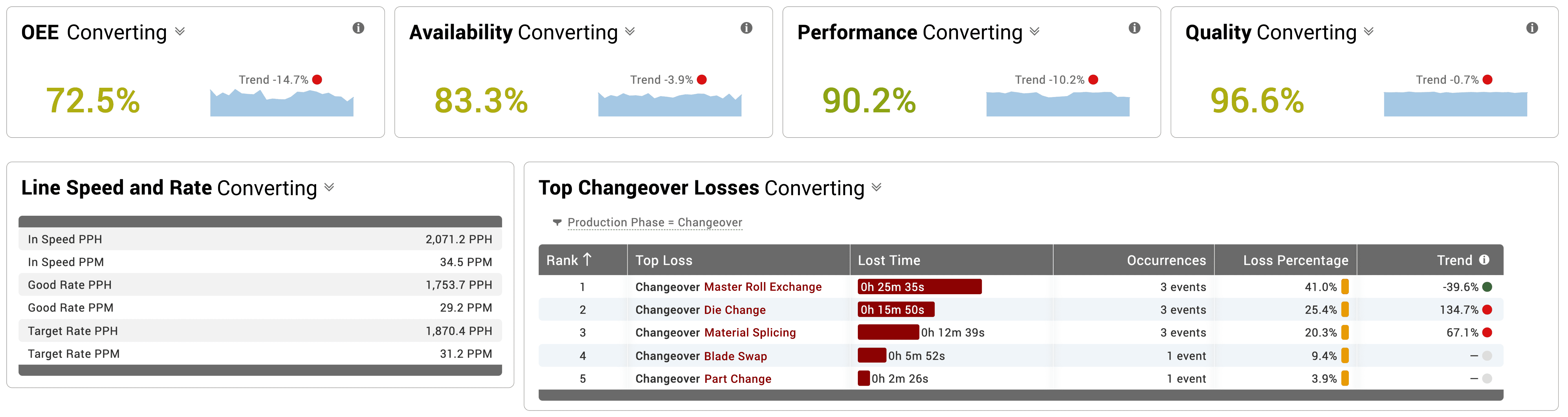

- 1Understand Changeover Variance Changing master rolls and splicing material is often a major loss of production time for pulp and paper manufacturers. Vorne XL provides accurate analysis of your changeover events, offering insights that help you set ambitious but attainable target times.

- 2Maintain Target Run Rates Utilize the real-time plant floor scoreboard and browser-based web interface to monitor current or historical run rates and speeds, ensuring the process is running optimally and meeting customer demand.

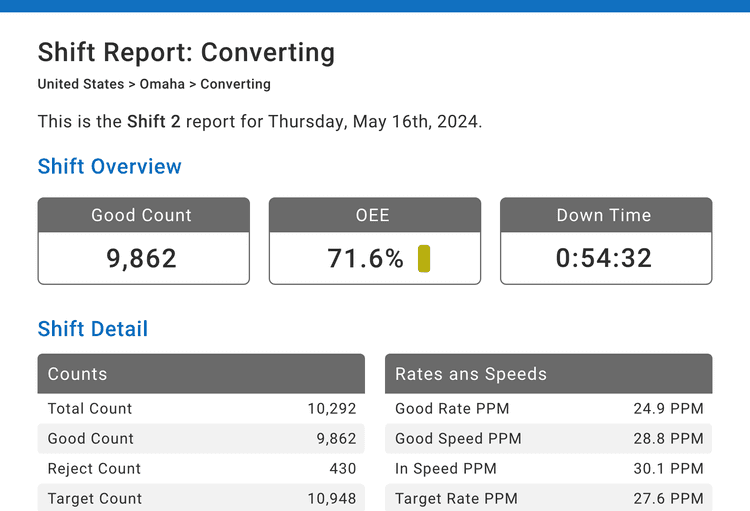

- 3Historical Part Run Data Reducing variance between shifts in operating the line is critical to manufacturing efficiently and effectively. Use historical part and shift data to develop best practices and to tailor specific training and corrective actions.

- 4Automated Enterprise Reporting XL enables you to automatically generate and send production reports for individual lines and for data that is aggregated across your entire plant - or even multiple plants. Stay informed with timely reports that place the appropriate data into the hands of the right people at the exact time they need it.

- 5Operator Comments Empower your operators or maintenance staff to record additional comments on events such as changeovers, downtime, or part runs, contributing to more robust reporting. Share any information that is useful for shift handoffs or process improvement over time.

Learn More About Vorne XL

We would be happy to show you XL, deep dive into your challenges and your processes, and answer any questions you may have. We also offer free 90-day trials. In fact, we have completed thousands of successful XL trials. Did you know that 92.8% of companies that try XL buy XL?

Metrics, Dimensions, and Dashboards

Vorne XL provides you with an incredible data foundation and an outstanding suite of reporting tools to effectively drive your continuous improvement, lean manufacturing, and digital transformation initiatives. With XL you get immediate access to over 100 highly accurate and actionable metrics and 20 data dimensions - in real time and for deep retrospective analysis through historical reporting. There are dozens of built-in reports, and you can easily create your own reporting dashboards.

Vorne XL User Success Stories

XL helps manufacturers in almost every industry improve their process productivity. You will love our free support, free software updates, 3-year warranty, transparent pricing, fast implementation, and of course, the wealth of product features. That is why we have so many customers that share their success stories.

Pulp and Paper Manufacturing Specialties

Our XL Productivity Appliance, with its fully integrated OEE reporting system, works well across an extremely broad range of pulp and paper manufacturing industry specialties. Here are some of the more common specialty areas where XL is used:

- Paper Bleaching

- Paper Calendering

- Paper Coating

- Paper Converting

- Paper Corrugating

- Paper Cutting

- Paper Drying

- Paper Folding

- Paper Making

- Paper Milling

- Paper Reel Handling

- Paper Roll Pressing

- Paper Roll Wrapping

- Paper Sheet Forming

- Paper Slitting

- Paper Stock Preparation

- Paper Winding

- Wood Chipping