Creating a Digital Twin in Manufacturing

What Is a Digital Twin in Manufacturing?

A Digital Twin is a precise, real-time, sensor-driven, digital representation of something physical (which we will refer to as the Physical Entity). In manufacturing, the Physical Entity can be the product you are manufacturing or the process you use to manufacture that product.

Digital Twins connect the physical and virtual worlds, creating a cycle in which changes in the physical world are captured, represented, and used to generate new insights.

Digital Twins differ from pure computer simulations because they use real-time sensor data to continually update their models to reflect a very accurate state of the Physical Entity. Ultimately, the goal of a Digital Twin is to continually improve the Physical Entity.

Examples of how these insights can be used include optimizing run time, predicting behavior (e.g., predictive maintenance), and testing what-if scenarios.

Creating a Digital Twin can be a complex undertaking. Most references describe using thousands of sensors to model the Physical Entity. While the potential is intriguing to be sure, for most applications thousands of sensors are not a practical short-term goal (especially when taking cost and time into consideration). Fortunately, there is a broad range over which a Digital Twin can be created - from very complex (thousands of sensors) to very simple (several sensors).

Let’s explore a practical alternative that you can apply to just about any manufacturing process: Using three sensors to create a Digital Twin of your process.

How to Create a Digital Twin in Manufacturing

Thousands of sensors is a bit overwhelming. Three sensors is immediately actionable. So let’s start with three sensors:

- In Count sensor at the start of your process

- Cycle sensor at the constraint of your process

- Out Count sensor (good or reject) at the end of your process

This configuration collects data from three essential points in your process: material entering the process (In Count); operation of the constraint step of the process - the key to optimization (Cycle); and finished product exiting the process (Out Count).

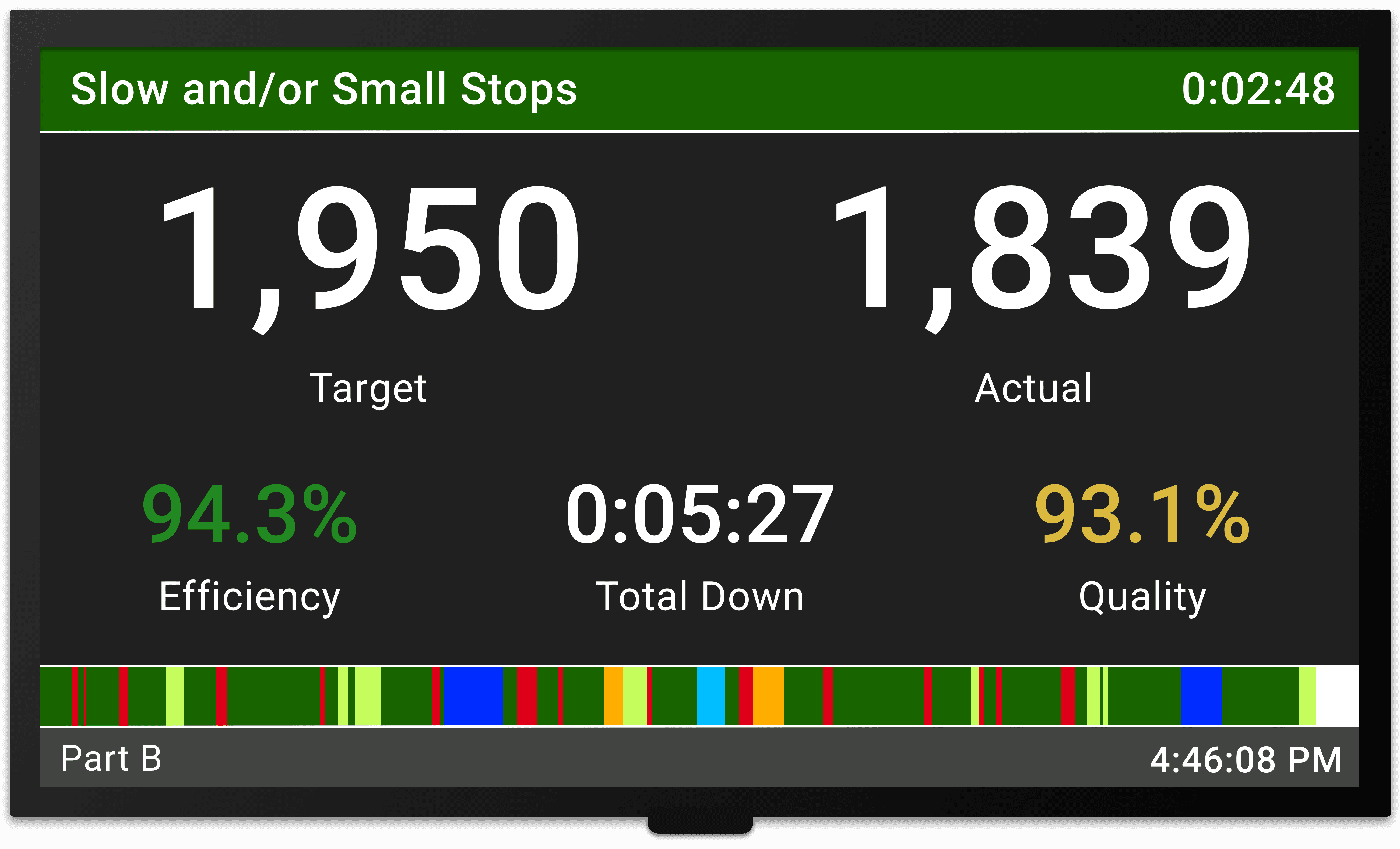

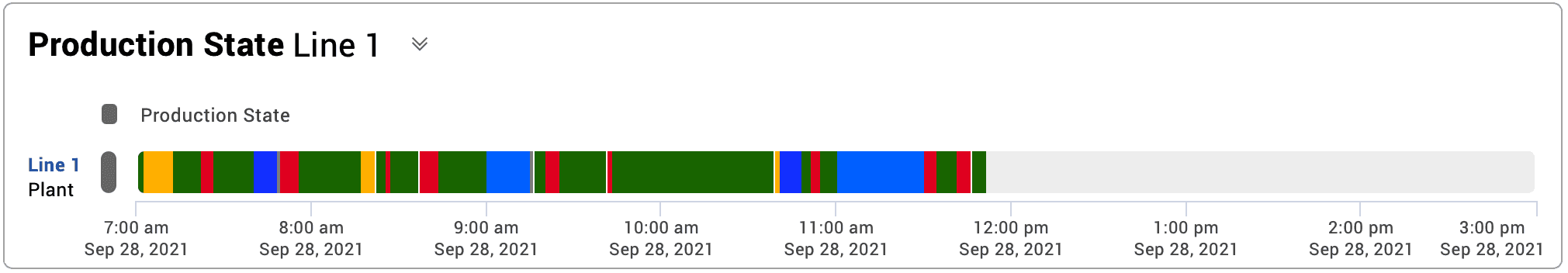

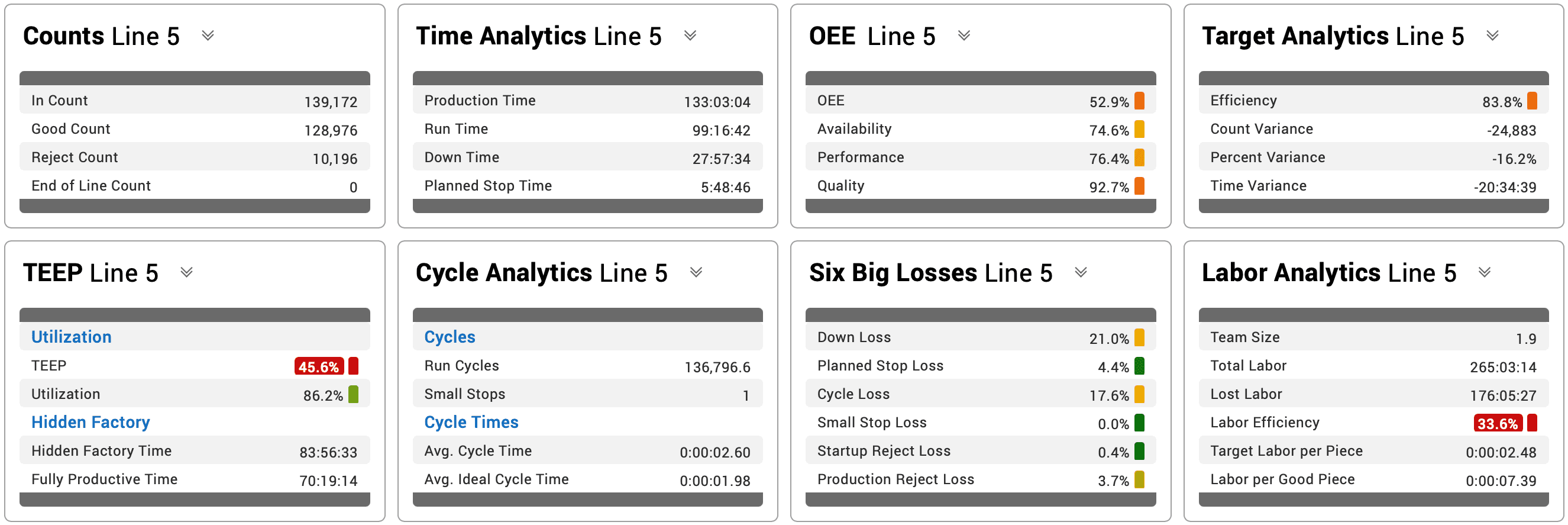

In this example, the Cycle sensor generates a model of the production process that populates data in real-time as the shift progresses (the shift below is about two-thirds complete).

This brings us to another interesting point - there is a tight relationship between the concept of a Digital Twin and the concept of a Data Model (i.e., abstract representation of information). Both create data-driven abstract models that emulate real-world entities. So the Digital Twin has its roots in long-standing methodologies for managing large quantities of structured data.

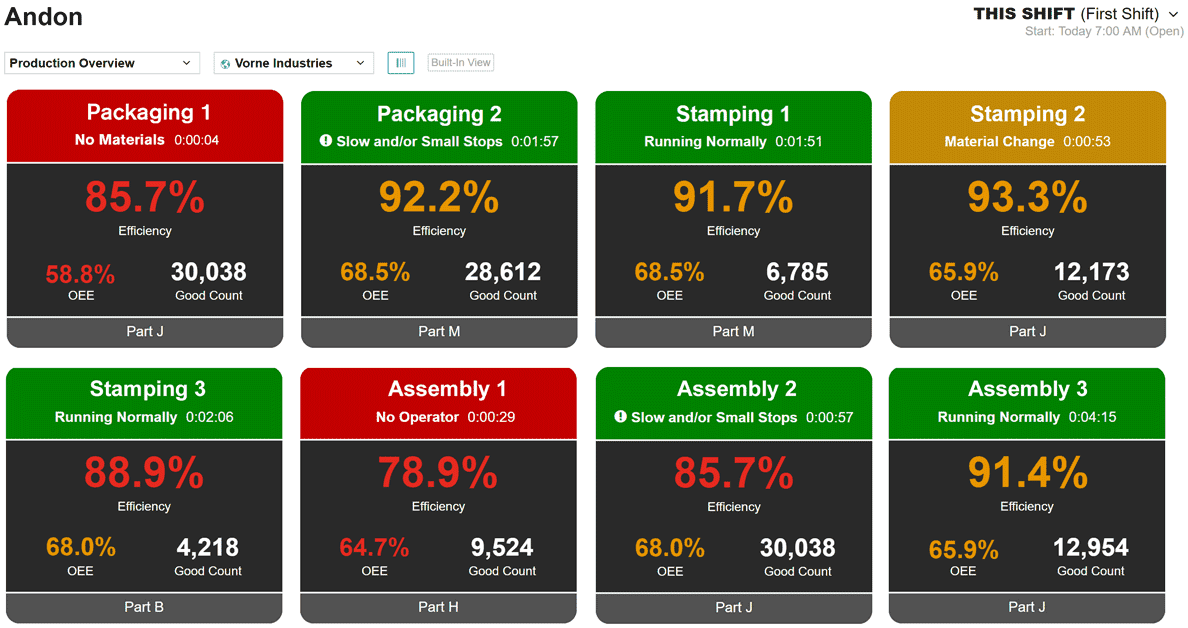

The real-time nature of the Digital Twin supports iterative improvement and enables manufacturers to continually fine-tune their processes and maximize efficiency. Here is an example of how the data collected from three sensors can be leveraged into a real-time view that includes Efficiency (for operational planning) and OEE (for tactical and strategic planning). This “Andon” view provides a clear summary of production in real-time so that everyone involved in the manufacturing process knows how each line is performing and where immediate action should be taken.

The three-sensor Digital Twin can be easily extended to model more aspects of the process. In other words, it supports an extensible Data Model.

What Are the Benefits?

What kind of benefits can you expect if you implement a three-sensor Digital Twin?

- Precise emulation of important aspects of your manufacturing process (e.g., counts, rates, cycle analytics, quality analytics, performance metrics)

- Real-time feedback for operators

- Much faster issue detection

- Insights into how to run at peak efficiency

- Reduction in product defects

- Reduction in downtime

In fact, the Data Model supported by the three sensors can generate over 100 manufacturing metrics, including OEE, TEEP, and Six Big Losses.

Imagine what you can accomplish when you are empowered with enough information to tell a “real” story of what is happening in your manufacturing process, and how to improve it. Imagine what you can accomplish with a three-sensor Digital Twin.